- Home

- >

News

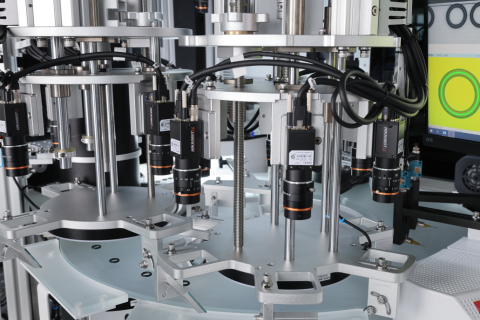

Automated Optical Screening Device for Six-Sided Flange Bolts The state-of-the-art equipment employs a vibratory feeder to sequentially place bolts onto an inspection platform. Utilizing advanced industrial CCD cameras with high resolution, the system captures a 360-degree image of each bolt for comprehensive examination.

As the product moves beneath the CCD sensor, the indexing platform halts, triggering a signal for the CCD to capture an image for comparison. The CCD processes the data, determining whether the product meets the quality criteria. If the product passes, the CCD sends another signal to the indexing platform, allowing it to proceed to the next work station for another image analysis. This continuous cycle repeats until all items are inspected, and they are then discharged into a frame.