News

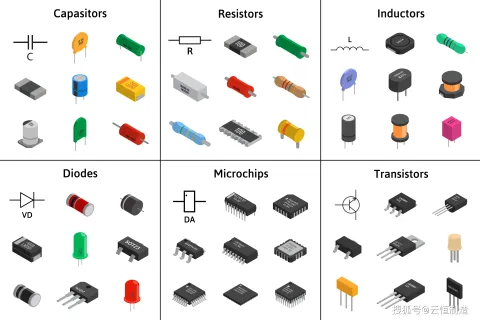

Electronic component manufacturing demands micron-level precision across high-volume production. As depicted in the provided image, miniature multilayered ceramic capacitors (MLCCs), low-temperature co-fired ceramics (LTCCs), chip-scale resistors/inductors, ICs, and ferrite cores require defect detection capabilities beyond human vision limits.

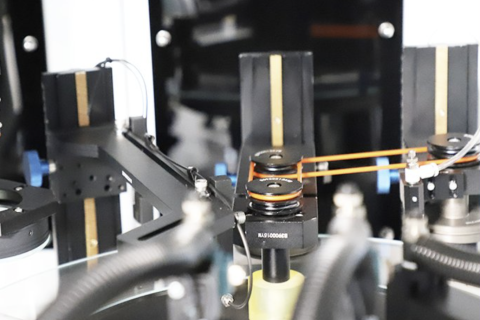

Fastener automated inspection devices are critical for ensuring the quality and efficiency of manufacturing processes. Proper assembly and debugging are essential to achieve high precision, stability, and reliability. This article synthesizes industry best practices for assembling and debugging these systems, drawing from technical standards and engineering expertise

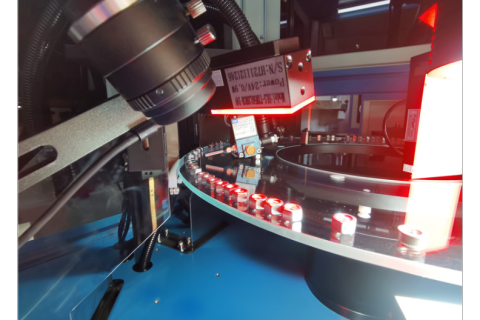

Machine vision systems – intelligent eyes powered by cameras (CMOS/CCD) and sophisticated image processing software – are fundamentally transforming production lines across the globe. Converting captured images into precise digital data, these systems analyze pixel patterns, brightness, and color to identify features and make real-time decisions, controlling machinery and ensuring unparalleled quality and efficiency.

The relentless drive towards miniaturization and hyper-connectivity places immense pressure on connector manufacturers. In this high-stakes arena, where a single micron-scale defect can lead to catastrophic system failures, the connector optical sorter has emerged as the indispensable guardian of precision and quality. This sophisticated machine is not just a quality control tool; it’s the bedrock of reliability for countless electronic devices powering our world.

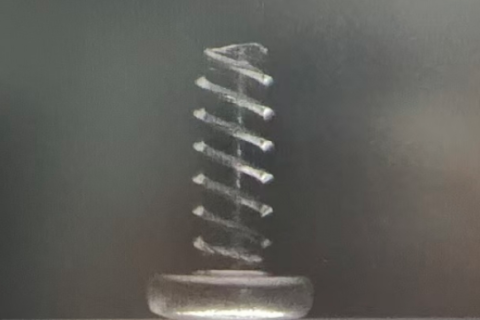

In the intricate world of precision fastening, the humble washer-fastener assembly (a screw combined with a pre-assembled washer) plays a crucial role. Whether ensuring proper load distribution, preventing loosening, or acting as a seal, the integrity of this bonded pair is paramount.

In today's demanding manufacturing landscape, ensuring the absolute precision and integrity of components like rivet caps is non-negotiable. Even minor defects – a minuscule scratch, a hair's breadth dimensional deviation, or a slight shape irregularity – can cascade into catastrophic product failures, costly recalls, and irreparable brand damage. The relentless pressure for perfection demands solutions beyond traditional manual inspection. Enter the Rivet Cap Optical Sorting Machine: an automated sentinel harnessing the power of light and artificial intelligence to safeguard quality at microscopic levels.

Unitecho’s fully automatic visual screening machines entail variable upfront costs depending on configurations. However, their long-term efficiency and precision often outweigh traditional manual methods, making them ideal for large-scale, high-accuracy manufacturing environments. By strategically selecting models and leveraging technological advancements, businesses can achieve significant cost savings while enhancing product quality.

Unitecho has achieved a major breakthrough in optical sorting technology, securing two national patents. According to the China National Intellectual Property Administration, the patents include the "Multi-Functional Optical Sorting Workstation" (Authorization No. CN222402392U) and the "Optical Image Sorting Machine with Automatic Material Centering Structure" (Authorization No. CN222402365U), filed in April and May 2024, respectively.

AI vision inspection systems typically require an operating temperature range of 20°C–30°C. High temperatures may cause overheating of electronic components and increased sensor noise, while low temperatures can lead to lubricant solidification or component frost. High-precision devices often require temperature compensation technology or additional cooling systems

In an era of precision and innovation, the optical sorting machine stands as a beacon of technological advancement. Harnessing the power of cutting-edge optics, these machines redefine the standards of accuracy and productivity in various industries. The art of design meets science as these devices seamlessly integrate sophisticated algorithms with sleek and compact designs.