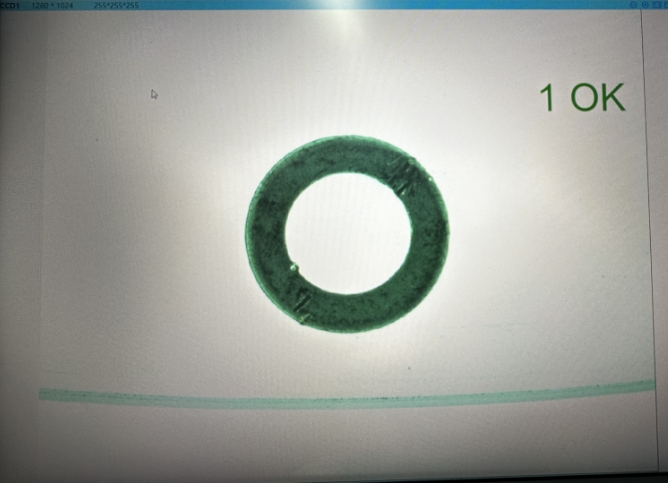

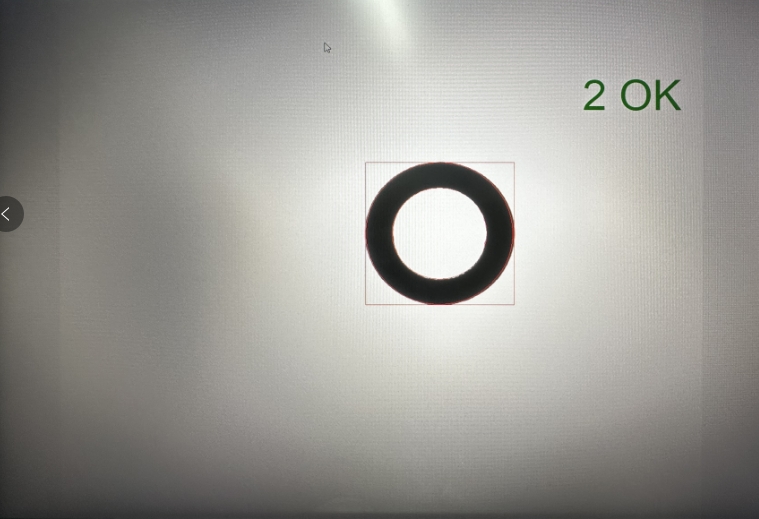

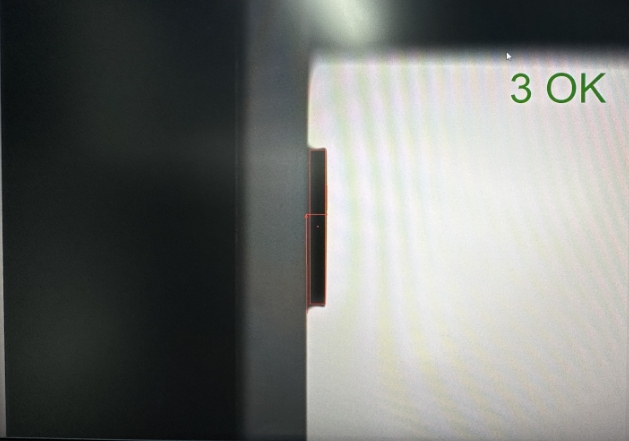

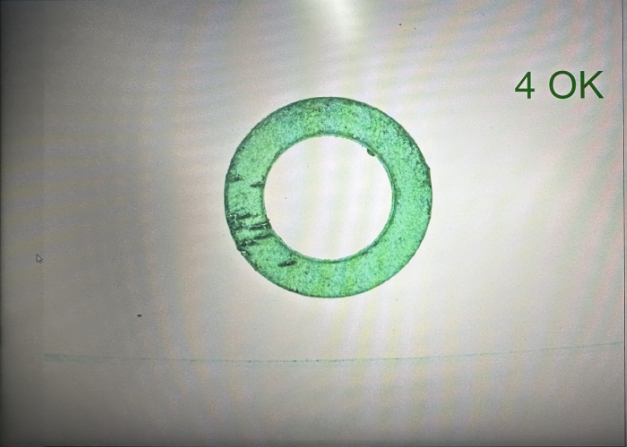

Optical inspection equipment for gasket screening

2024-10-19 17:26Optical inspection equipment for gasket screening is a high-precision device that employs advanced cameras to capture comprehensive images of gaskets. Utilizing sophisticated image processing algorithms, it analyzes these visuals to identify defects such as black spots, scratches, dents, foreign matter on the gasket surface. Key dimensions like diameter, thickness, and flatness are also precisely measured. Based on predefined standards, the system autonomously differentiates between acceptable and defective gaskets, streamlining the sorting process.

This technology plays a pivotal role in industries like automotive, machinery, electronics, and chemicals, specifically within the gasket manufacturing segment. By enhancing the efficiency and quality control in gasket production, it reduces production costs, minimizes defective items, and ultimately boosts overall productivity. The implementation of optical inspection significantly contributes to improving product consistency, ensuring compliance with strict industry standards, and facilitating a more sustainable and profitable manufacturing workflow. As a result, businesses can gain a competitive edge and save substantial resources by leveraging this advanced technology.