- Home

- >

- News

- >

- indusdry news

- >

News

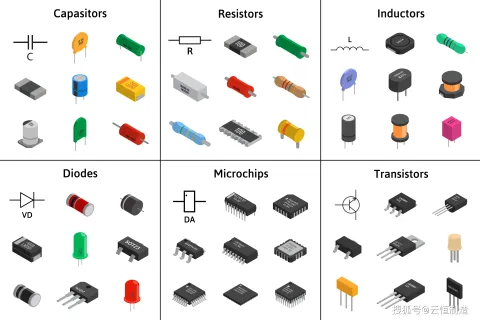

Electronic component manufacturing demands micron-level precision across high-volume production. As depicted in the provided image, miniature multilayered ceramic capacitors (MLCCs), low-temperature co-fired ceramics (LTCCs), chip-scale resistors/inductors, ICs, and ferrite cores require defect detection capabilities beyond human vision limits.

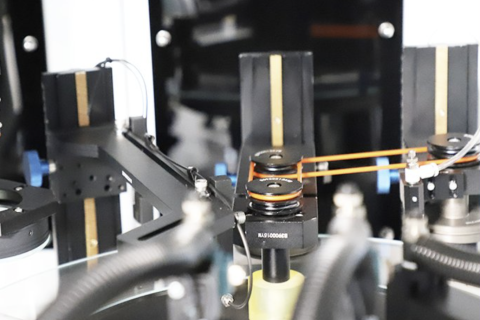

Fastener automated inspection devices are critical for ensuring the quality and efficiency of manufacturing processes. Proper assembly and debugging are essential to achieve high precision, stability, and reliability. This article synthesizes industry best practices for assembling and debugging these systems, drawing from technical standards and engineering expertise

Machine vision systems – intelligent eyes powered by cameras (CMOS/CCD) and sophisticated image processing software – are fundamentally transforming production lines across the globe. Converting captured images into precise digital data, these systems analyze pixel patterns, brightness, and color to identify features and make real-time decisions, controlling machinery and ensuring unparalleled quality and efficiency.

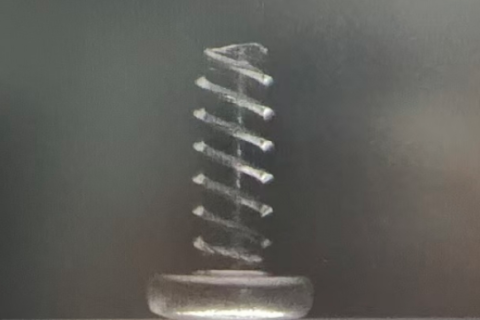

In the intricate world of precision fastening, the humble washer-fastener assembly (a screw combined with a pre-assembled washer) plays a crucial role. Whether ensuring proper load distribution, preventing loosening, or acting as a seal, the integrity of this bonded pair is paramount.

Unitecho’s fully automatic visual screening machines entail variable upfront costs depending on configurations. However, their long-term efficiency and precision often outweigh traditional manual methods, making them ideal for large-scale, high-accuracy manufacturing environments. By strategically selecting models and leveraging technological advancements, businesses can achieve significant cost savings while enhancing product quality.

AI vision inspection systems typically require an operating temperature range of 20°C–30°C. High temperatures may cause overheating of electronic components and increased sensor noise, while low temperatures can lead to lubricant solidification or component frost. High-precision devices often require temperature compensation technology or additional cooling systems

Automated Optical Screening Device for Six-Sided Flange Bolts The state-of-the-art equipment employs a vibratory feeder to sequentially place bolts onto an inspection platform. Utilizing advanced industrial CCD cameras with high resolution, the system captures a 360-degree image of each bolt for comprehensive examination.

A combination of shims and screws is inspected using an Optical Sorting Machine, a sophisticated piece of equipment designed for high-speed image analysis. High-speed cameras capture clear images of both components, which are then transmitted to a computer system for meticulous processing.

In the realm of precision engineering, screws and nuts play a pivotal role. However, despite their importance, manufacturing imperfections can sometimes affect their visual appearance. Here's an overview of some common defects that may be observed:

In today's fast-paced manufacturing environments, the efficiency of tight screw detection and sorting is paramount. Screw sorters, specifically designed for this purpose, have revolutionized the process by significantly boosting productivity and accuracy in the assembly line.