The screw optical inspection machine

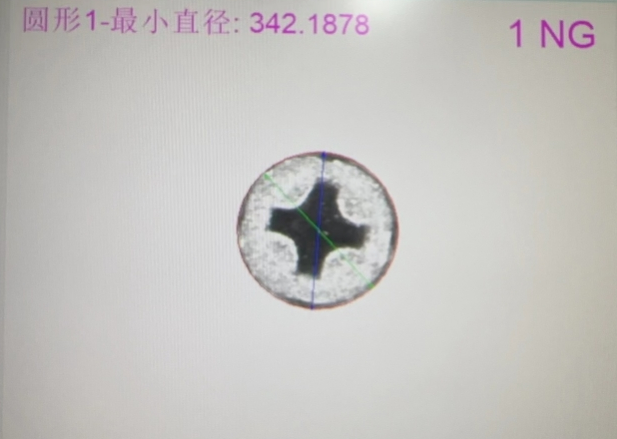

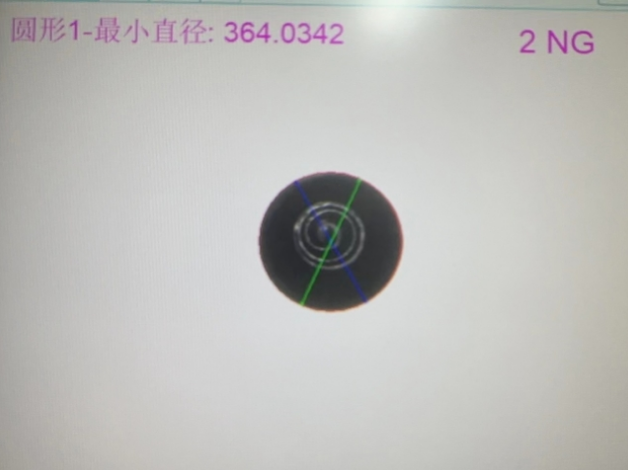

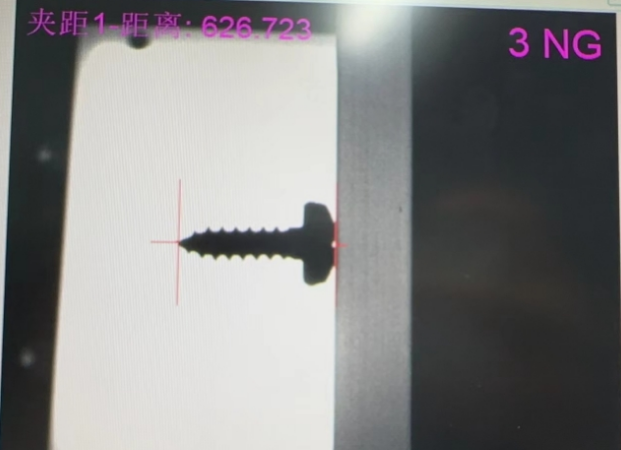

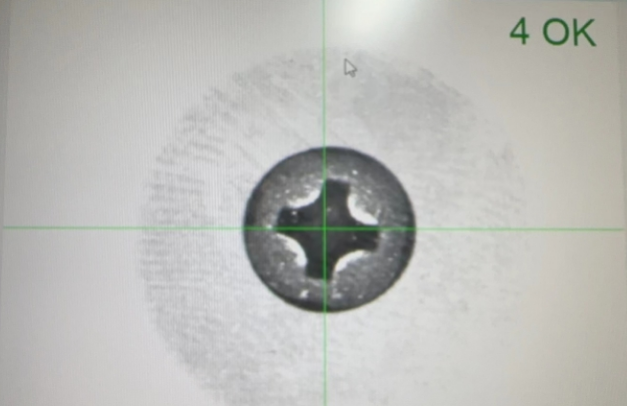

2024-10-19 17:33The screw optical inspection machine integrates cutting-edge optical imaging technology, artificial intelligence algorithms, and precise mechanical components, revolutionizing the inspection process for screw manufacturing. Equipped with high-speed industrial cameras, it captures comprehensive images of screws, followed by intelligent image analysis software that swiftly detects variations in size, surface defects, thread damage, and material flaws. This ensures that every screw leaving the factory meets the most stringent quality criteria.

According to the team leader, "The traditional manual inspection method was not only inefficient but also prone to human errors, leading to missed detections or misjudgments. Our machine has completely resolved these issues, delivering automation, intelligence, and exceptional accuracy, boosting both productivity and product quality."

The introduction of this screw inspection system not only fulfills the urgent demand for high-quality and efficient devices in the nuts manufacturing sector but also sets a new benchmark for the industrial automation upgrade across manufacturing industries. As Industry 4.0 and smart manufacturing gain momentum, this equipment is poised to be widely adopted in various sectors, driving the industry towards greater sophistication and precision in its manufacturing processes.