Optical Sorting Machine for High-Speed Detection and Quality Control of Shim-Screw Assemblies

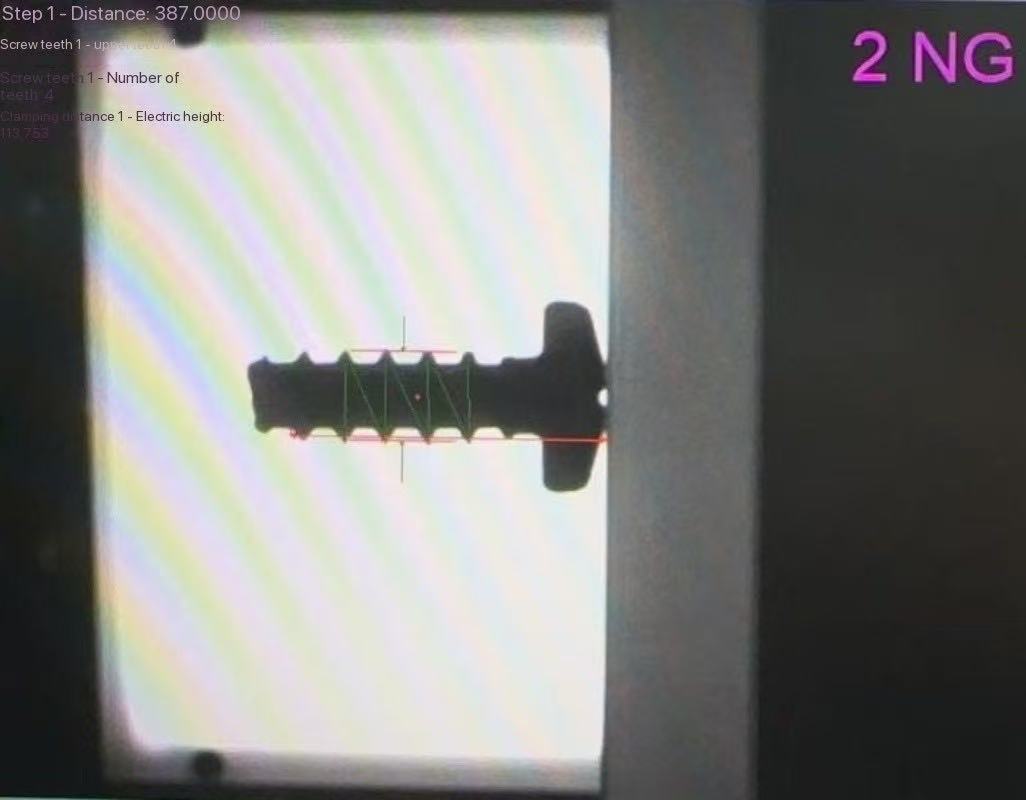

2024-12-30 18:23A combination of shims and screws is inspected using an Optical Sorting Machine, a sophisticated piece of equipment designed for high-speed image analysis. High-speed cameras capture clear images of both components, which are then transmitted to a computer system for meticulous processing. The system employs cutting-edge image processing algorithms to evaluate key parameters, such as dimensions, shape, and surface defects of the shims and screws. Any discrepancies that fall below the established quality standards are instantly detected by the machine, resulting in their immediate removal from the production line.

This real-time inspection ensures uninterrupted workflow and maintains product consistency. The system's ability to identify and reject defective parts not only enhances productivity but also safeguards the integrity of the manufacturing process and the final product's reliability. By integrating precision and automation, this technology optimizes efficiency while minimizing errors, contributing to the overall excellence of the manufacturing industry.