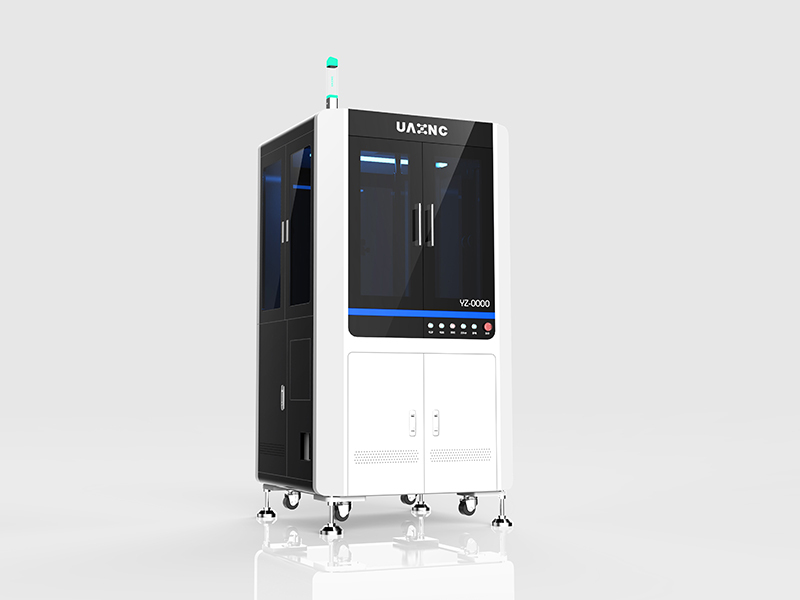

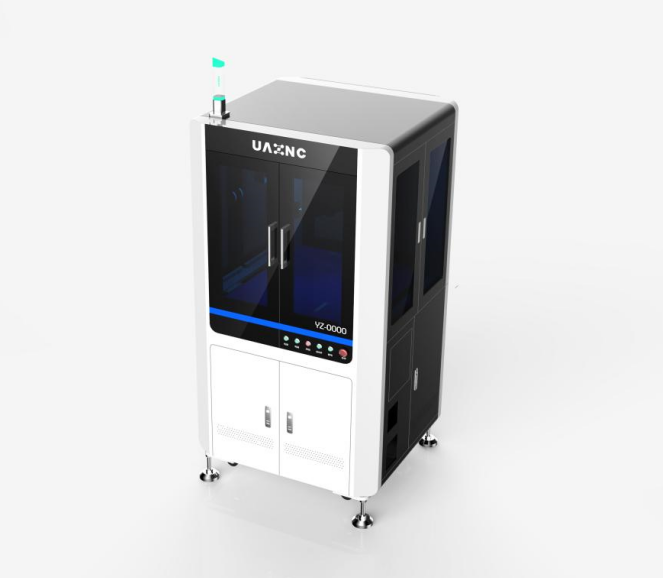

Six-face detection equipment

1. Automated, reducing human error & fatigue.

2. Enhanced speed and productivity.

3. Accurate & consistent inspection.

4. Cost-effective & scalable for diverse products.

- Unitecho

- China

- 15days

- 1500

- Information

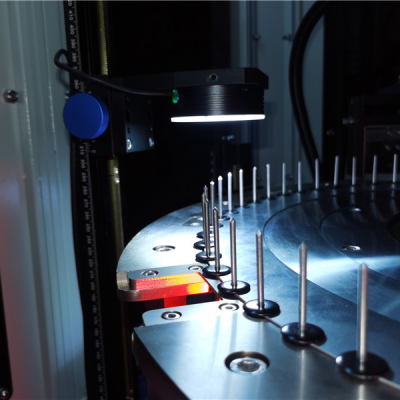

Six-face detection equipment workprinciple

The working principle of an industrial inspection device is based on image analysis from industrial cameras. This equipment is capable of customizing various functional tests for product quality, such as visual checks for issues like reversed polarity, misplaced insulation, uneven sleeve edges, liquid leakage from caps, unbanded items, open or improperly sealed ends, protrusions larger than 0.2mm, defective caps, misclassification, poor soldering points, color variations, and missing pins. It also performs dimensional assessments, including length, width, height, hole diameter, and specific local dimensions. Primarily designed for small, non-stationary items, the device addresses common challenges in manual inspection, like high labor requirements, slow speed, and increased risk of missed defects.

By deeply understanding industry-specific requirements, the device was developed to mitigate errors resulting from human fatigue or inconsistency. Over recent years, visual inspection systems have gained popularity due to their efficiency, intelligence, and non-contact nature, gradually replacing manual inspections in industries. These systems have become widely adopted, offering a more reliable and consistent solution to quality control.