AI Appearance Inspection Equipment

1. Precise visual inspection via AI technology.

2. Real-time defect detection, minimizing waste.

3. Scalable to adapt to various product types.

4. Streamlines manufacturing processes, saves time.

- unitecho

- China

- 15days

- 1500

- Information

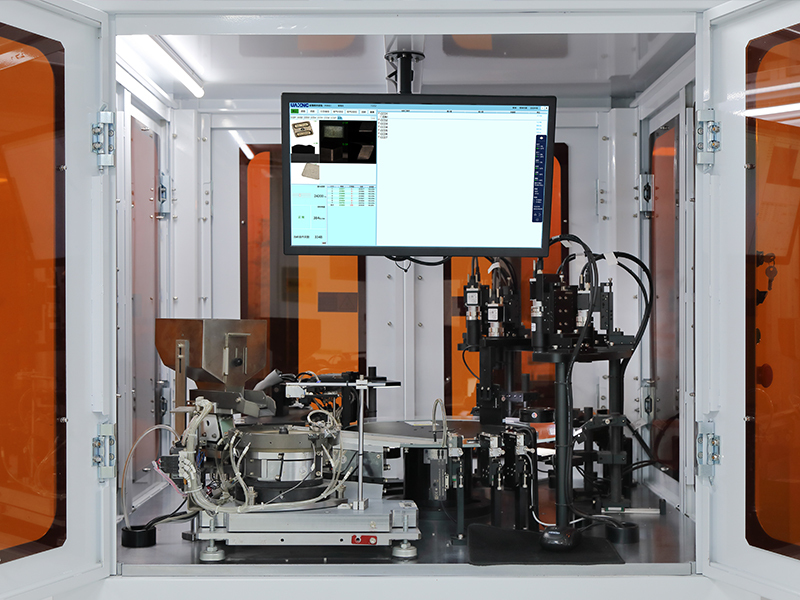

AI Appearance Inspection Equipment description

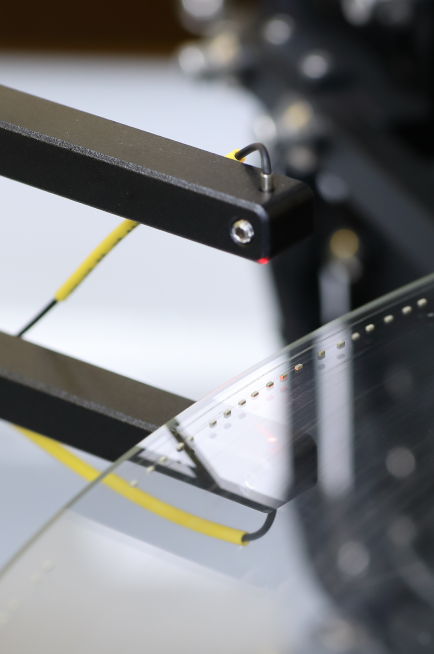

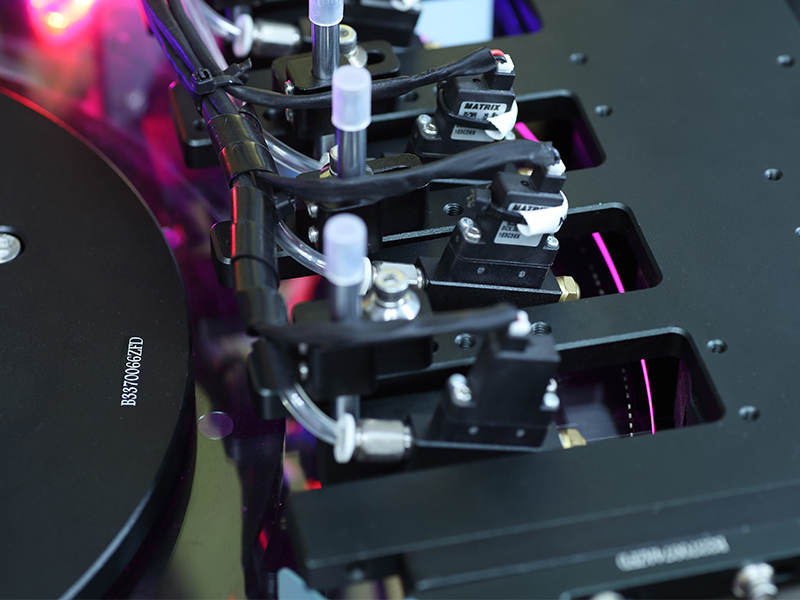

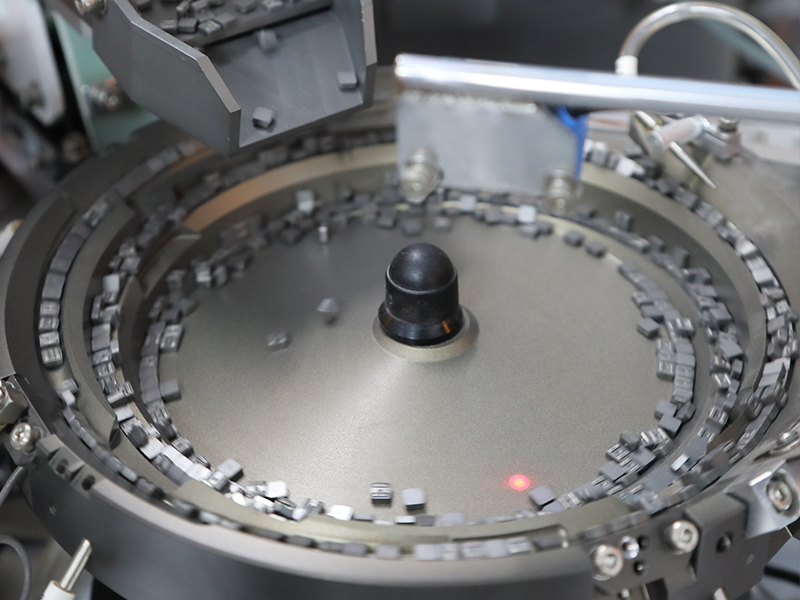

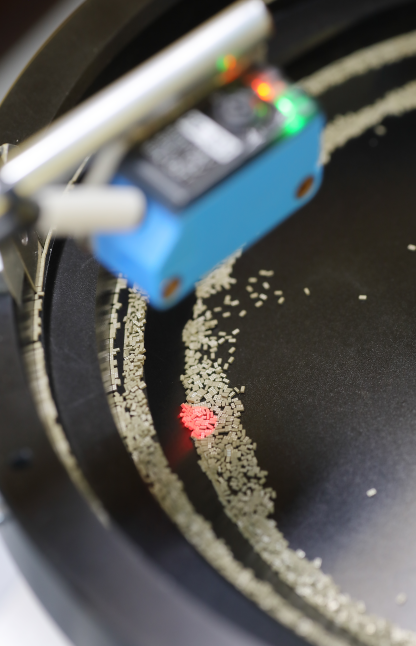

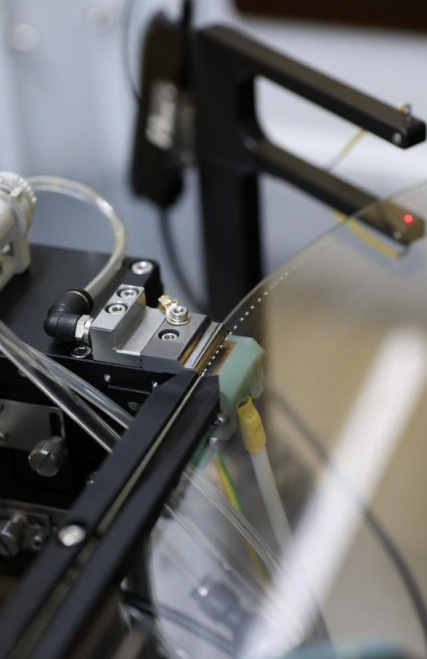

AI Appearance Inspection Equipment leverages cutting-edge machine learning algorithms and computer vision to function. The system begins by capturing high-definition images or video of products during the manufacturing process. These inputs are fed into a deep neural network, trained specifically to recognize patterns and anomalies associated with ideal product appearance.

The core principle involves feature extraction, where the equipment identifies key details such as color consistency, shape, and texture. It compares these attributes against pre-defined standards set by the manufacturer. Using pattern recognition, it can differentiate between minor defects and those requiring intervention.

Through continuous learning, the AI improves its accuracy over time, reducing the need for manual human inspection. In case of any irregularities, it triggers an alert, which is then reviewed by a supervisor or automated response for immediate action. This not only enhances efficiency but also ensures consistent quality control in real-time, enhancing overall production efficiency and customer satisfaction.