Automated Quality Control System

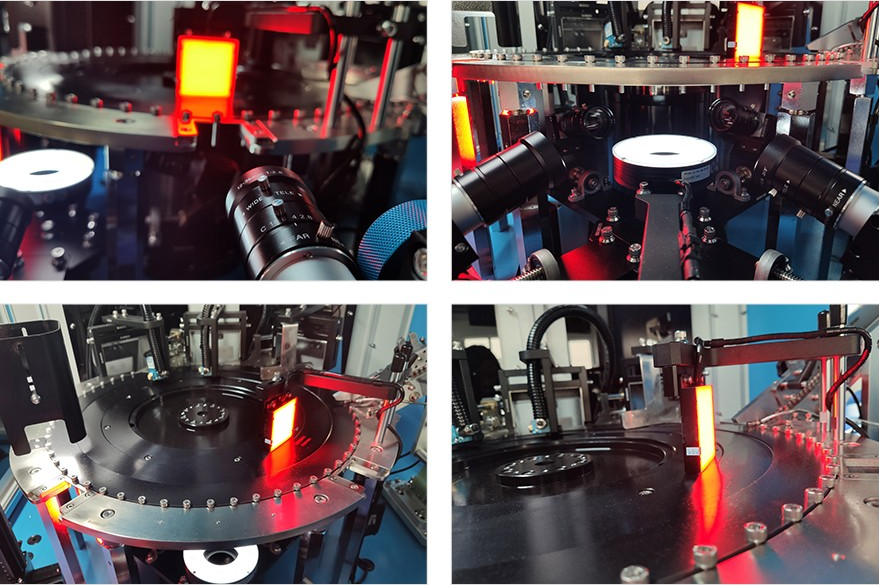

This Indexing disc pin type optical screening machine is designed for the detection of screws and hanging parts that cannot stand. It supports the installation of up to 4 cameras and a 360-degree inspection for defects such as thread damage, cracks, and bending. Optional features include line scan cameras and bend detection.

Customizations are available for three-part assembly separation detection where standing is not possible. The system can be enhanced with an automated carousel, packaging machine, and automatic feeding system, all based on client requirements. Color options for the device are available in blue and white. The Indexing disc pin type optical screening machine checks dimensions like thickness, diameter, edge-to-edge and corner-to-corner alignment, bending, cracks, thread damage, cross-threading, and dents on the surface.

- unitecho

- China

- 30days

- 300

- Information

- Download

Indexing disc pin type optical screening machine UFP-DR-V specification

| Equipment general technical parameters table | |

|---|---|

| Equipment type | UFP-DR-V |

| Equipment size | 1250*1250*2100 |

| Overall weight | 950kg |

| communication | Network port (OPC/WebAPI, TCP/IP, SQLServer) |

| Voltage | 220V/50Hz |

| Atmospheric pressure | 0.5-0.8Mpa |

| Equipment technical parameters table | |

|---|---|

| Check workpiece size | Rod diameter 2-22mm, length 5-120mm; Head diameter2.5-30mm, diameterdiameter1 -30mm |

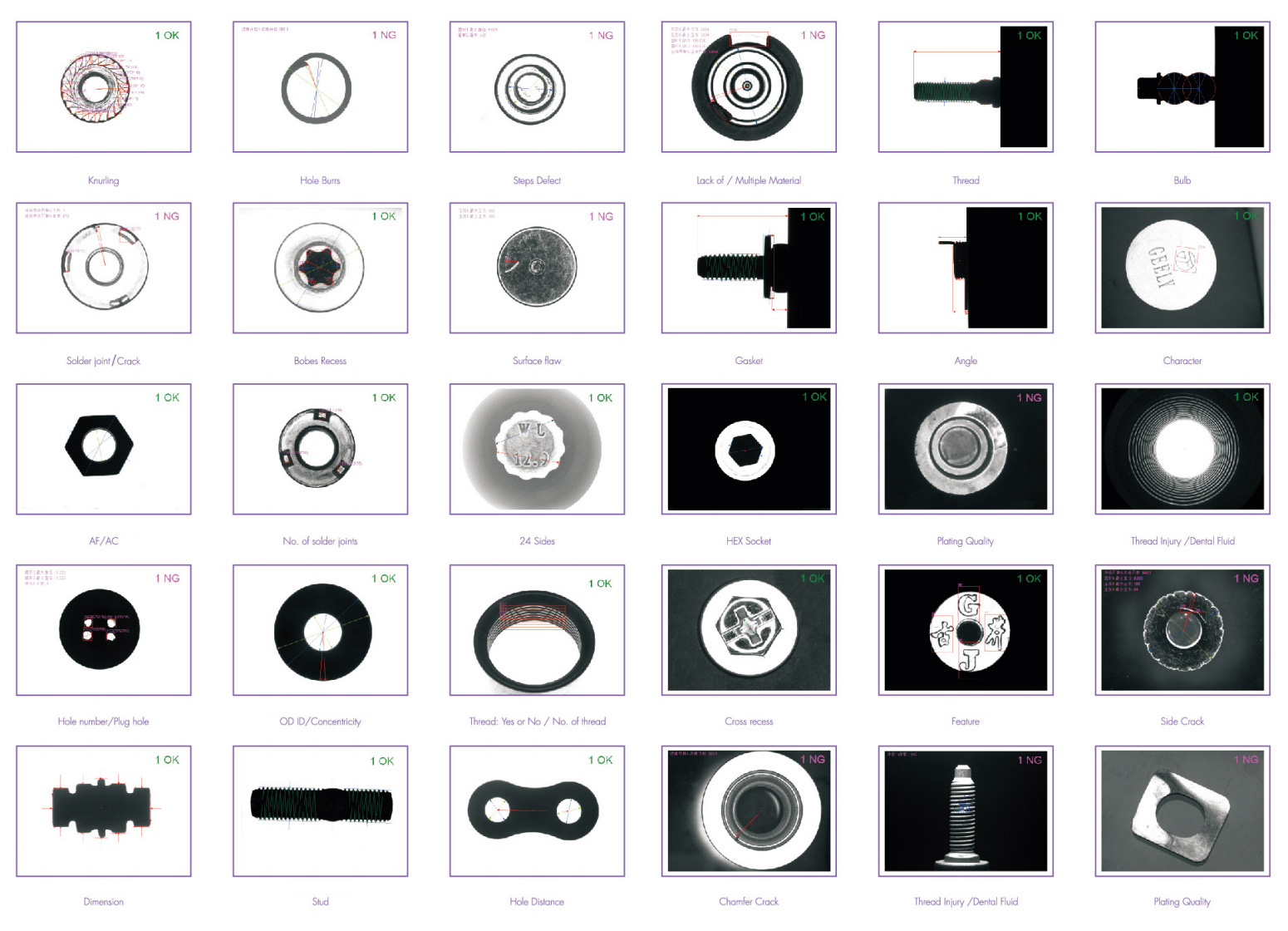

| Test item | Thickness, diameter, outer diameter of teeth, opposite Angle, curvature, cracking, teeth damage pits and other dimensional appearance defects |

| Detection speed | 250 PCS /min |

| Software system | Independent R&D |

| Detection accuracy | ≥士0.005mm |

| Hd camera | Bassler, Hikon |

| Loading mechanism | Vertical loading machine, climbing machine, etc |

| Optical glass disc | Diameter 500mm, thickness 8mm |

| Industrial computer | Industrial grade computer |

| Discharge opening | 3-6 receiving boxes (optional according to customer demand) |

Indexing disc pin type optical screening machine feature

Custom-built Solutions to Tailor to Individual Needs

Fully Automated Testing, Reducing 80% Manual Inspection Costs

High-tech, advanced with superior precision, stability, and reliability; user-friendly operation.

Smooth and Accurate Operation

Ensuring seamless detection and assembly without vibrations or shocks during the process.

Instant Data Display & Intelligent Judgement

Automated "Pass" or "Reject" decision based on real-time data.

Equipped with German-made CCD High-Resolution Camera

Reliable performance and outstanding image quality.

Integrated Automation Capabilities

Compatible with automatic conveyors and assembly systems for seamless material handling and output automation.

Layout:

Custom-built Solutions to Tailor to Individual Needs

Fully Automated Testing \- Reducing 80% Manual Inspection Costs

High-tech, advanced \- superior precision, stability, & reliability \- user-friendly operation

Smooth & Accurate Operation

Ensures smooth detection & assembly \- no vibrations or shocks during the process

Instant Data Display & Intelligent Judgement

Automated "Pass" or "Reject" decision based on real-time data

Equipped with German-made CCD High-Resolution Camera

Reliable performance \- exceptional image quality

Integrated Automation Capabilities

Compatible with auto conveyors & assembly systems - seamless material handling & output automation.

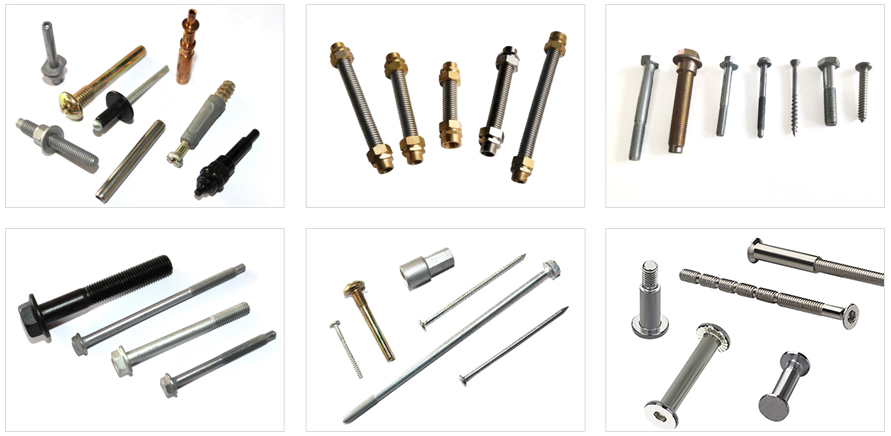

Indexing disc pin type optical screening machine application

Indexing disc pin type optical screening machine details

Indexing disc pin type optical screening machine UFP-DR-V

Indexing disc pin type optical screening machine AI platform