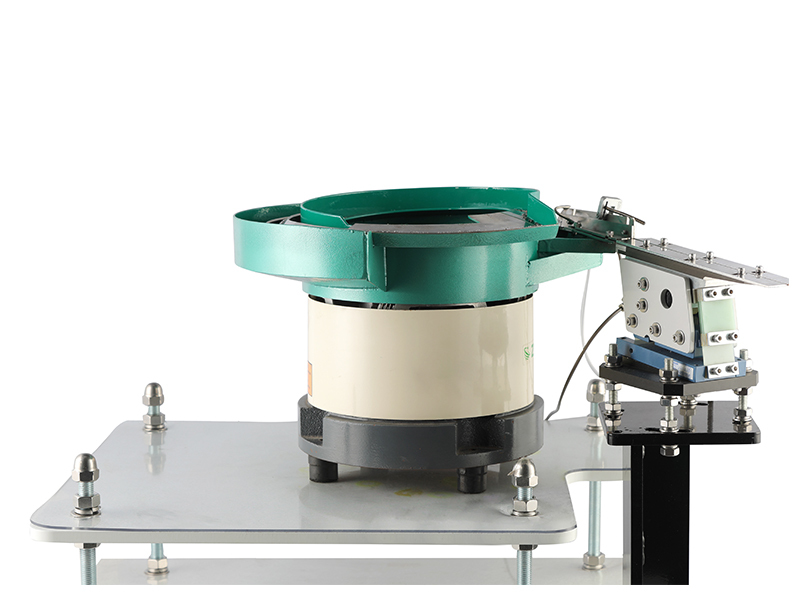

Auto Image Screening Equipment for Screw Fastener Nut Parts

High-Speed Inspection: Capable of rapid and precise inspection, it streamlines the quality control process, reducing manual labor and increasing efficiency.

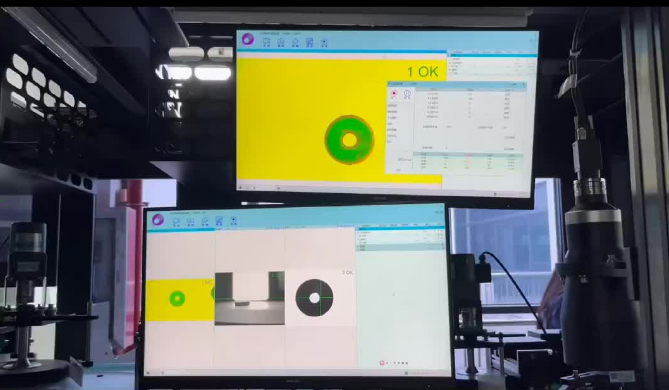

Advanced Image Recognition: Utilizing advanced computer vision algorithms, it can accurately detect defects, such as thread damage, dimensional variations, or surface flaws, with exceptional accuracy.

Non-Destructive Testing: The system employs non-invasive methods to inspect without damaging the nuts, ensuring product integrity and reliability.

- Unitecho

- China

- 15days

- 1500

- Information

Auto Image Screening Equipment for Screw Fastener Nut Parts Detection items include

Dimensional Specifications: Measuring parameters like length, diameter, and pitch accuracy.

Internal Obstructions: Identifying blocked or occluded interior cavities.

Hole Size: Ensuring consistent hole diameters.

Profile Accuracy: Confirming the correct curvature of the nut.

Coating Integrity: Detecting defects in the plating or coating process.

Impact Damage: Identifying scratches, dents, or pressure-induced damage.

Sharp Edges: Detecting burrs or irregularities along the rim.

Contamination: Identifying mixed materials or foreign particles.

Flaking or Loss of Paint: Examining paint integrity.

Surface Blemishes: Assessing the surface smoothness or presence of dents.

Symmetry Check: Verifying the evenness of the nut's shape.

Geometric Compliance: Ensuring adherence to specified profile tolerances.

Color Consistency: Detecting variations in color across the part.

Device Function

The hexagonal socket screw optical sorting machine serves as an efficient replacement for manual inspection by utilizing a visual imaging system. It automatically identifies defects in the product's appearance through digital image analysis. By employing a CCD (Charge-Coupled Device) camera to capture the target and convert it into image signals, these signals are processed by a specialized image processing system. The system analyzes pixel distribution, brightness, and color information, converting it into digital data, which is further processed to extract features from the image. Based on this evaluation, the machine controls the equipment's actions to make accurate decisions regarding product classification.

Key functions of the device include automatic feeding, precise positioning, automated inspection, sorting between pass and fail products, automated unloading, intelligent control, automatic statistical analysis, AI-based deep learning capabilities, and complete automation of the entire process.