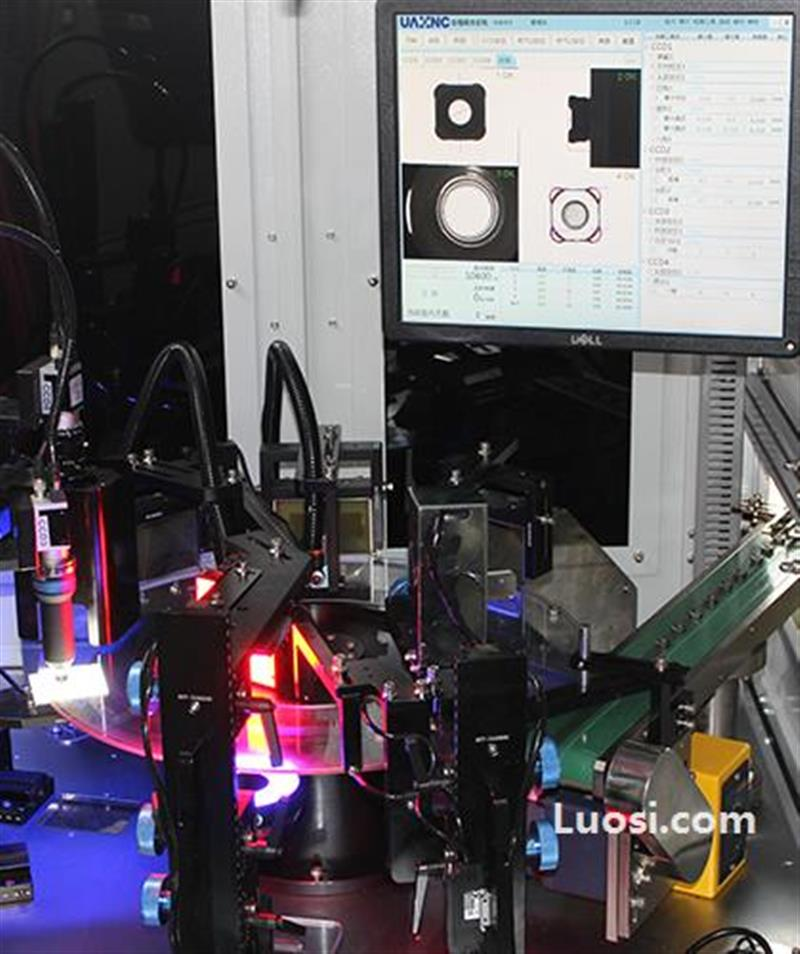

Indexing disc continuous optical screening machine

1, suitable for non-standing screws and bolts and pendable workpiece detection.

2, can be installed with 1-4 cameras +360° tooth damage, cracking detection, optional line scan camera, curvature detection.

3, can be specially customized, can not stand 3 combined workpiece separation detection.

4, according to customer needs, increase the turnover system, automatic packaging machine and automatic feeding system.

5, equipment color customization (blue, white).

- Unitecho

- China

- 30 days

- 30000

- Information

Indexing disc continuous optical screening machine UFC-DR-IV specification

| Equipment general technical parameters table | |

|---|---|

| Equipment type | UFC-DR-IV |

| Equipment size | 1250*1250*2100 |

| Overall weight | 850kg |

| communication | Network port (OPC/WebAPI, TCP/IP, SQLServer) |

| Voltage | 220V/50Hz |

| Atmospheric pressure | 0.5-0.8Mpa |

| Equipment technical parameters table | |

|---|---|

| Check workpiece size | Rod diameter 2-26mm, length 5-115mm; Head diameter2.5-28mm, diameter1-35mm |

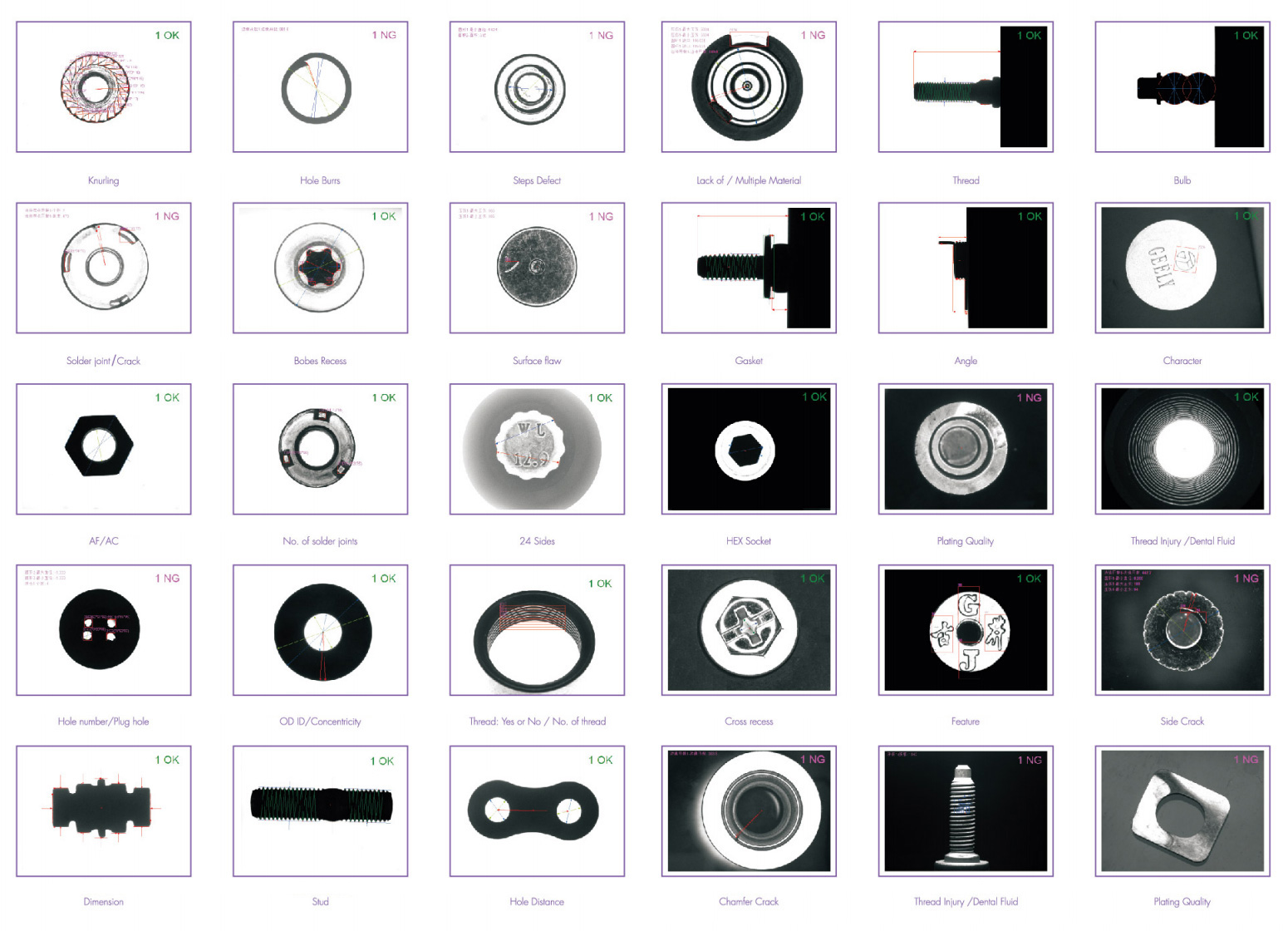

| Test item | Thickness, diameter, opposite Angle, curvature, cracking, tooth damage, oblique teeth, pits and other dimensional appearance defects |

| Detection speed | 500PCS /min |

| Software system | Independent R&D |

| Detection accuracy | ≥士0.005mm |

| Hd camera | Bassler, Hikon |

| Loading mechanism | Vertical loading machine, climbing machine, etc |

| Optical glass disc | Diameter 500mm, thickness 5mm |

| Industrial computer | Industrial grade computer |

| Discharge opening | 3-6 receiving boxes (optional according to customer demand) |

At present, machine vision has successfully been employed in industrial inspection, with custom surface defect detection machines significantly enhancing product quality and reliability. It contributes to maintaining production speed by ensuring accurate checks on various processes, such as:

1. Packaging print quality inspection for products.

2. Container quality inspection in the beverage industry.

3. Beverage filling level monitoring.

4. Sealing integrity testing for drink products.

5. Lumber inspection in sawmills.

6. Quality control of semiconductor integrated circuits during packaging.

7. Sheet metal quality assessment in rolled steel products.

8. Fruit grading through automated visual analysis.

These applications demonstrate the versatility and effectiveness of machine vision technology across diverse manufacturing sectors.

Indexing disc continuous optical screening machine Defect Detection Case

Indexing disc continuous optical screening machine AI platform

1.The self-developed Al training platform UiD! supports customers to independently train Al models and lowers the threshold for Al implementation in the industry.

2.The self-developed defect generation software UiDG supports the rapid generation of defect samples when replacing diferent batches of products and completes model construction.