Optical inspection machine with a CBN

Customizable in design, it caters to diverse user requirements.

Adopting full automation, it reduces manual inspection costs by 80%.

Featuring high-tech content with advanced technology, excellent precision, stable operation, and reliable performance, it's user-friendly and ensures consistent quality.

During the inspection and assembly process, it exhibits smoothness, accuracy, and absence of vibrations or shocks, maintaining optimal conditions.

Equipped with German-made high-resolution CCD cameras, it boasts dependable quality and satisfactory performance.

It can be integrated with automated feeding and assembly systems, enabling material handling and assembly to be fully automated for seamless operations.

- unitecho

- China

- 15days

- 30000

- Information

Indexing disc continuous optical screening machine specification

| Equipment general technical parameters table | |

|---|---|

| Equipment type | UFC-C-IV |

| Equipment size | 850*850*2100 |

| Overall weight | 750kg |

| communication | Network port (OPC/WebAPI, TCP/IP, SQLServer) |

| Voltage | 220V/50Hz |

| Atmospheric pressure | 0.5-0.8Mpa |

| Equipment technical parameters table | |

|---|---|

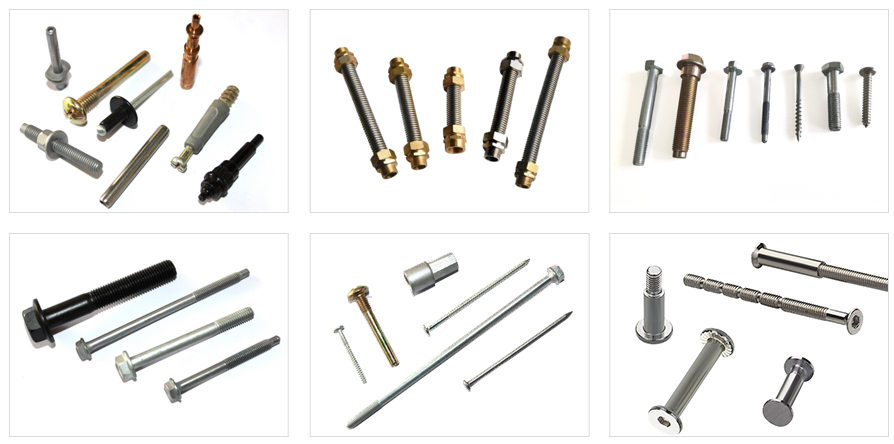

| Check workpiece size | Rod diameter 2-18mm, length 5-55mm; Head diameter2.5-28mm, diameterdiameter1-30mm |

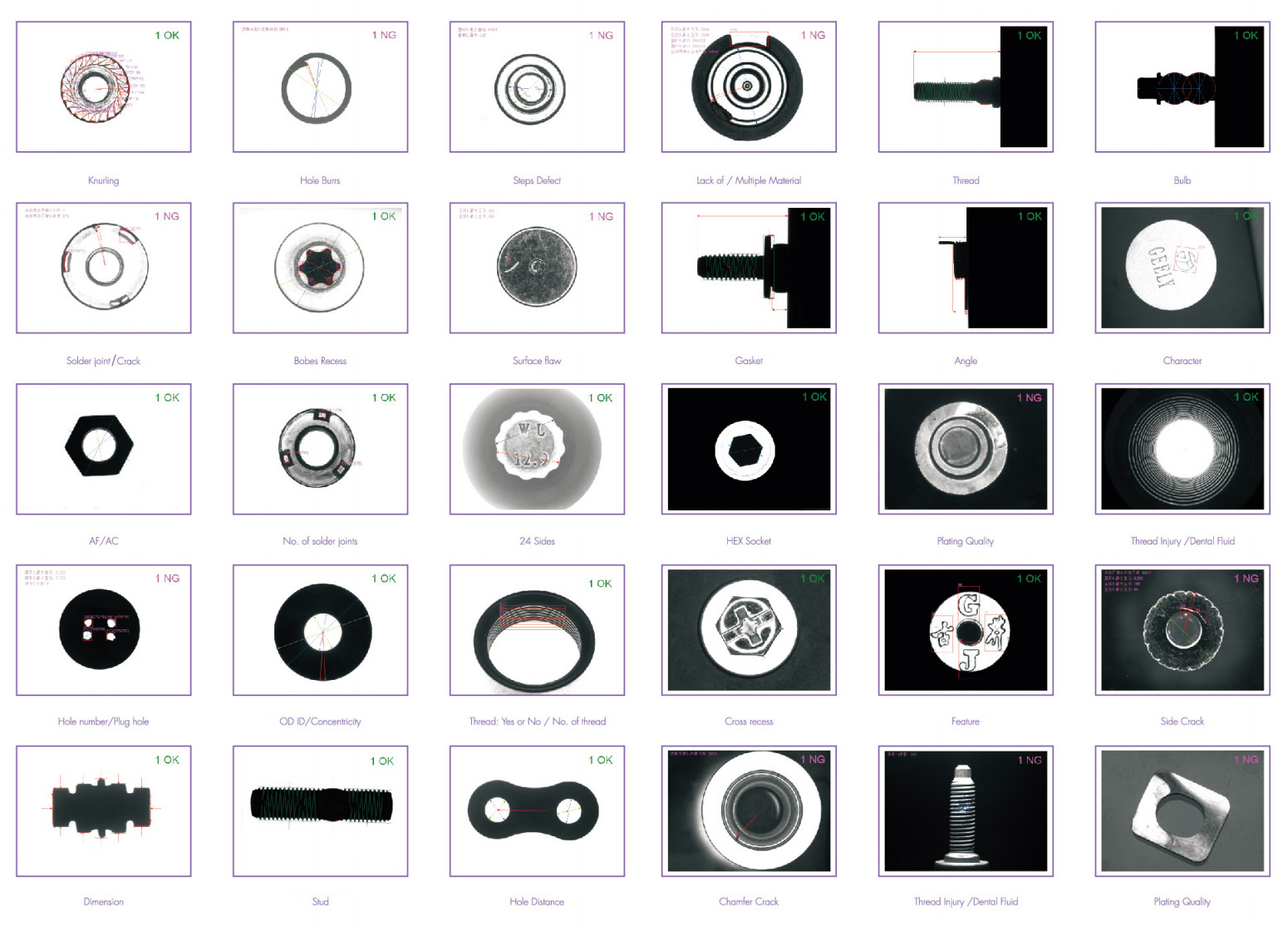

| Test item | Thickness, diameter, opposite corners, hole blocking, cracking, characters, pits and other dimensions of appearance defects |

| Detection speed | 450PCS /min |

| Software system | Independent R&D |

| Detection accuracy | ≥士0.005mm |

| Hd camera | Bassler, Hikon |

| Loading mechanism | Vertical loading machine, climbing machine, etc |

| Optical glass disc | Diameter 300mm, thickness 3mm |

| Industrial computer | Industrial grade computer |

| Discharge opening | 3-6 receiving boxes (optional according to customer demand) |

The Screw Optical Imaging Screening Device (Automated Screw Inspection System on a Continuous Production Line) operates based on the principle of visible object visual detection. It employs industrial cameras to convert the inspected screws into image signals by capturing their appearance. These signals, which consist of pixel distribution, brightness, and color data, are then converted into digital format. The image processing system performs various computations on these signals to extract features of the screws, such as area, count, position, and length. The device further evaluates the results against predefined tolerances and other criteria, outputting information on dimensions, quantity, and potentially any other quality parameters. This technology ensures efficient and accurate sorting and inspection of screws in manufacturing processes.

Indexing disc continuous optical screening machine Defect Detection Case

Indexing disc continuous optical screening machine