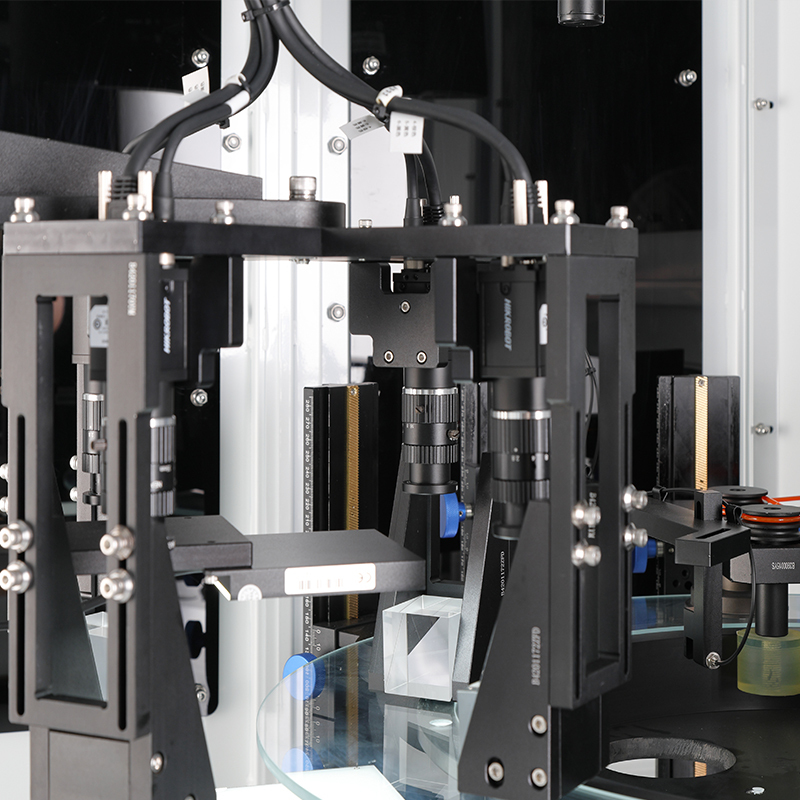

Glass disc type optical screening machine

The core feature of this cutting-edge device lies in its exceptional utilization of glass for its superior transparency, enabling seamless integration onto a glass work surface and facilitating precise detection capabilities. The glass disc it operates with boasts a substantial diameter of 600 millimeters and a sturdy 6-millimeter thickness. Utilizing a belt conveyor-based feeding mechanism, it ensures efficient material handling across a broad range of dimensions – from a slender 5 millimeters to a substantial 100 millimeters.

This innovative system is designed to accommodate versatile camera configurations, allowing for the installation of up to five high-resolution imaging systems. To enhance versatility further, it offers the possibility of incorporating both internal and external 360-degree lenses, tailoring the inspection experience to meet specific customer requirements. In addition to its inherent functionality, the device can be easily enhanced with optional features such as automatic packaging machines and an automated feeding system, streamlining the entire production process according to the client's exact specifications.

- unitecho

- China

- 30 days

- 30000

- Information

Glass disc type optical screening machine

| Equipment general technical parameters table | |

|---|---|

| Equipment type | Glass disc type optical screening machine UGV-600 |

| Equipment size | 1060x1060x1850mm |

| Workpiece diameter | 5-120mm |

| Total length of work | 2-150mm |

| Number of cameras | 1-5支 |

| Disc diameter | 600mm |

| Screening accuracy | ≧±0.002mm |

| Detection speed | ≦1000PCS /min |

| Air pressure specification | 5KG |

| Hd camera | Balser |

| Lens | Unitecho custom |

| Mainframe computer | Industrial grade computer |

| Detection software | Independent R&D |

| Electrical parts | Internationally renowned brand |

| Voltage | 220VAC(routine) |

| frequency | 50HZ/60HZ |

| Power | 3KW |

| Machine weight | 800KG |

Glass disc type optical screening machine feature

This image screening machine utilizes industrial cameras that leverage the high transparency of glass to enable stable and rapid placement of objects onto the inspection surface. Additional cameras can be installed at the bottom of the glass plate for simultaneous two-sided inspections of objects free from oil stains. Following the acquisition of images, an industrial computer, coupled with an AI software system developed in-house by the research team, compares the image patterns in an automated, cost-effective, and high-performance manner. Consequently, the system streamlines boring and labor-intensive manual tasks, reduces human error, significantly improves product quality, and strengthens the company's competitive position in the market.

Hardware Configuration:

The hardware setup consists of an automated system designed for efficiency, safety, and labor cost savings, which includes a vibratory feeder, a delivery track, and a testing platform. Here's a translation of each component:

· Vibratory Feeder: The feeder serves as a container for the probes to be tested. It utilizes vibration to convey the probes towards the delivery track.

· Delivery Track : This is the mechanism that transports the probes, with those coming off the vibratory feeder moving systematically along the track until they reach the inspection platform for examination.

These components work together seamlessly to streamline the probe handling process.

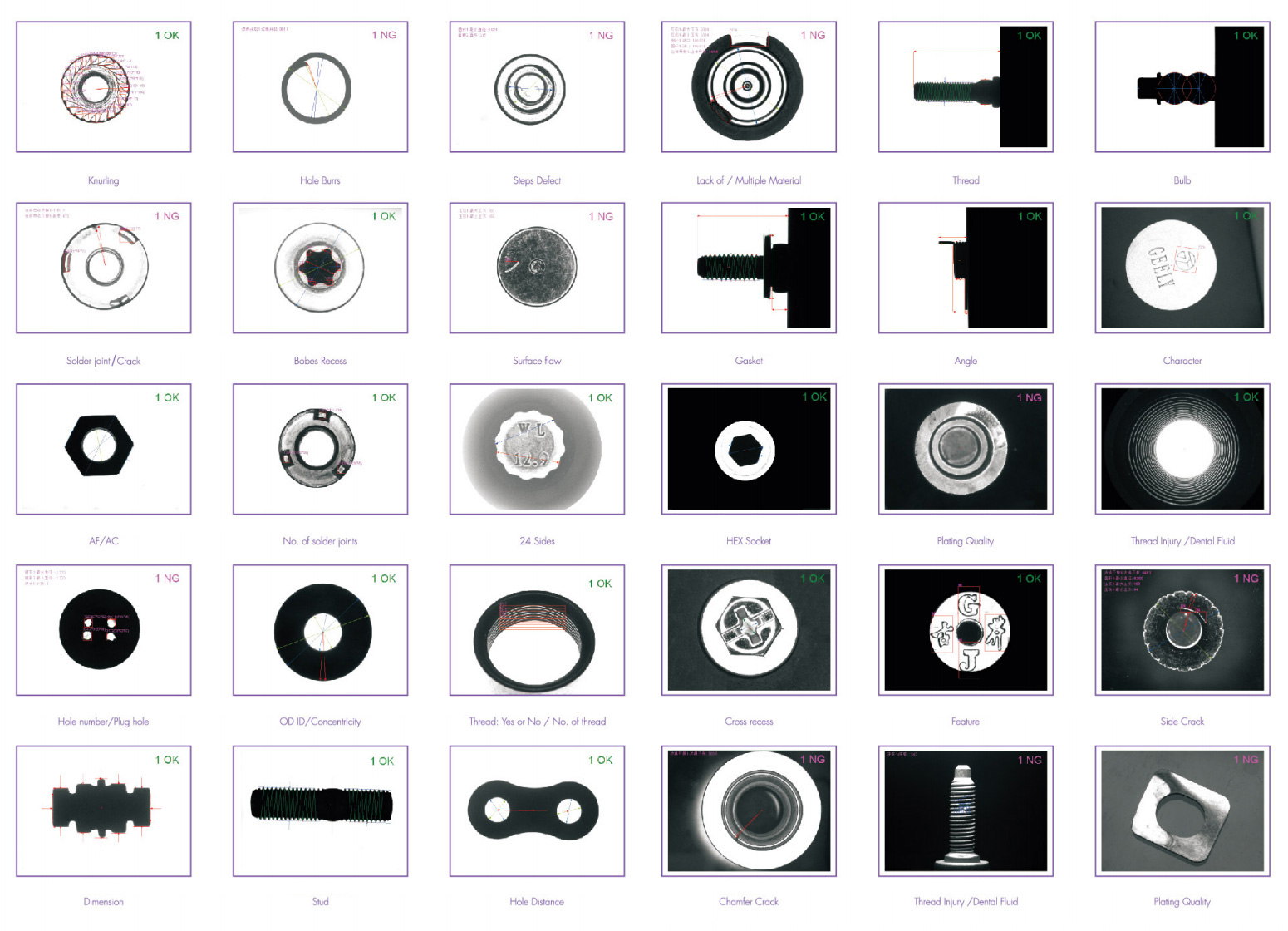

Glass disc type optical screening machine Defect Detection Case

Glass disc type optical screening machine