Resistance visual inspection equipment

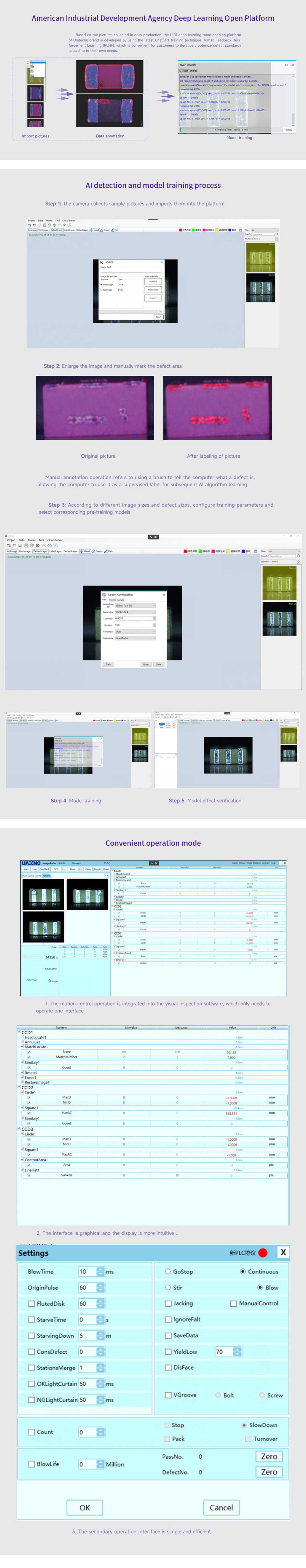

Design: Aesthetically pleasing and user-centric machine chassis;

System: Multi-functional and intelligent software platform;

Operation: Streamlined one-touch operation workflow;

Interface: Intuitive and simplified user interface for ease of use.

- unitecho

- China

- 90days

- 300

- Information

Resistance visual inspection equipment Specification

| Equipment Speed | |||||

|---|---|---|---|---|---|

| British system size | 0201 | 0402 | 0603 | 0805 | 1206 |

| (Pcs/min)R | 6000 | 7000 | 5000 | 3500 | 3000 |

| Equipment technical parameters table | |

|---|---|

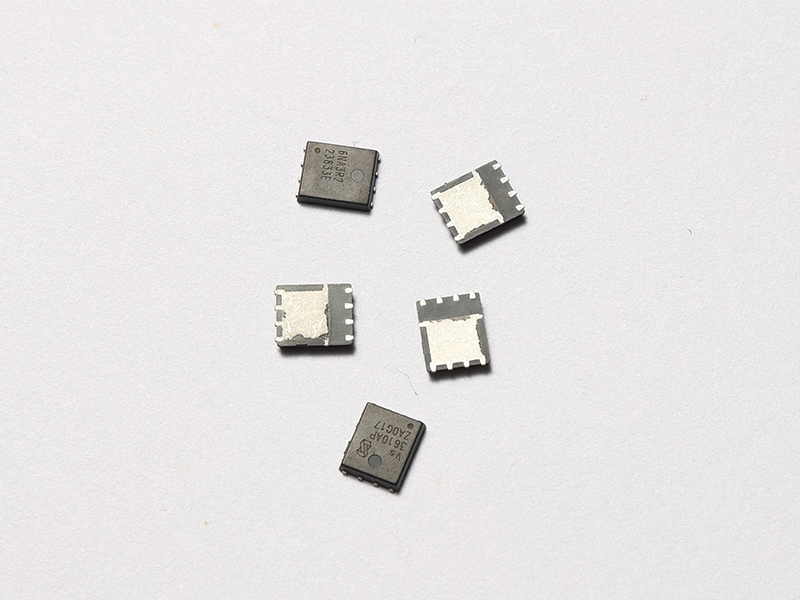

| Detecting element | Patch resistance |

| Detection size | British system 0201、0402、0603、0805 etc |

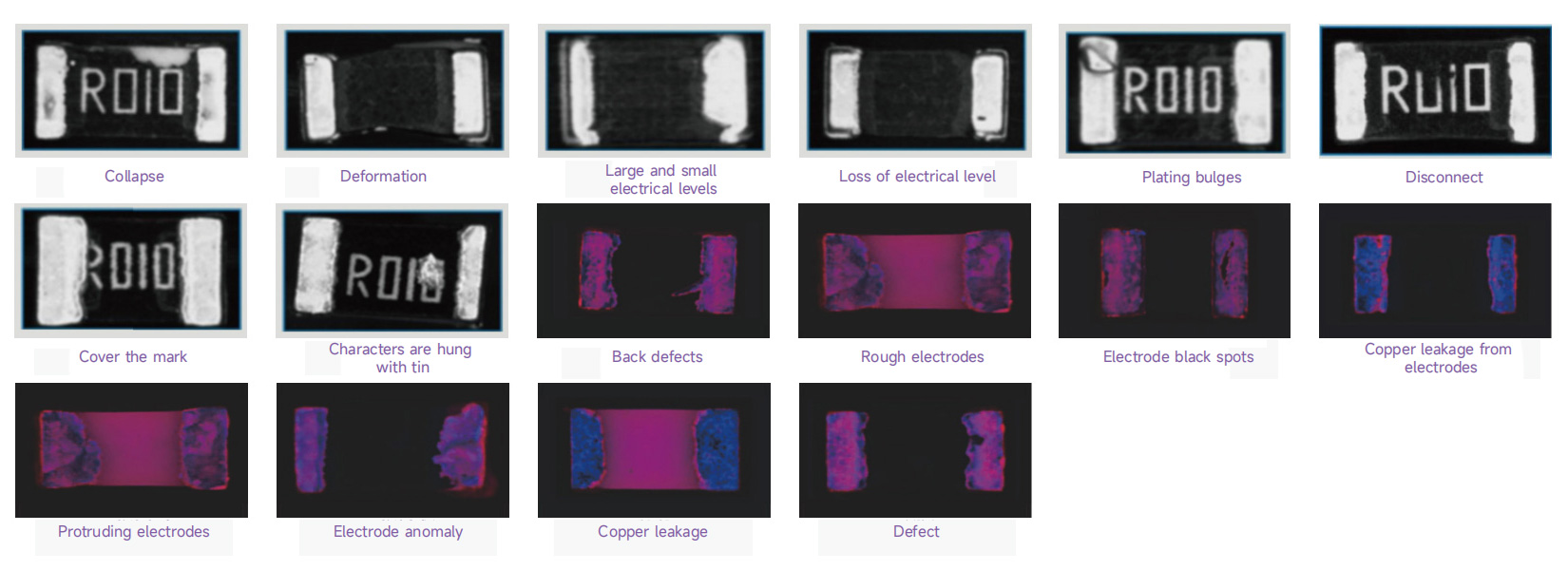

| Test item | Electrode size, porcelain body size, damage, missing, dirty, discoloration, cracks, abnormal font, etc |

| Detection station | 6-side detection |

| Detection sorting | 4 bins(customizable)OK*1, NG*2, Undetected*1 |

| CCD | 0.4M Pixels, USB3.0 Vision, Color*6, Sony CMOS |

| Illuminant | High brightness dual color dual channel |

| Resolution | 2.3 μm pixels,3.45 μm pixels,4.6 μm pixels,6.9 μm pixels |

| Speed | Max 290fps |

Resistance visual inspection equipment

Inspection items: Rust, tin peeling, contamination, abnormal font, color discrepancy of the main body, deformation, cap marking missing, electrode deficiency, excess glue, and inadequate glue.

The state-of-the-art Six-Sided Visual Inspection Machine, designed and developed in-house with proprietary software, is a highly efficient and versatile solution for precision defect detection in a wide range of products. Catering to diverse sectors such as plastics (like syringe seals), metal components (cold-drawn parts), and electronic electronic components (capacitors, inductors, resistors), this cutting-edge machine excels at detecting defects with unrivaled accuracy.

Equipped with an AI model that expertly classifies anomalies, it boasts a comprehensive set of features including real-time defect indicators for deformities, burrs, cracks, scratches, and contamination. Its remarkable speed of up to 1,000 to 2,000 pieces inspected per minute ensures seamless production flow without compromising quality – achieving an amazing precision level of 5 microns.

The sleek and user-centered design, reflecting high aesthetic standards, provides optimal ergonomics for operators. The intelligent software system combines multifunctionality with user-friendly automation, enabling one-touch operation even for less experienced users. The intuitive graphical interface simplifies navigation, making it easy for all to comprehend and utilize.

Our proprietary software not only enhances performance but also carries intellectual property rights, ensuring our commitment to innovation and security. The Six-Sided Visual Inspection Machine is the epitome of reliable and efficient visual inspection, revolutionizing the way manufacturers monitor and maintain product integrity in today's competitive landscape.

Resistance visual inspection equipment