LED visual inspection equipment

The high-speed feeding system embodies advanced automation, enabling efficient and rapid material delivery with exceptional precision and accuracy, ensuring uninterrupted productivity in manufacturing processes. Similarly, the high-speed motion control module signifies cutting-edge dynamics, capable of executing quick and precise movements, delivering exceptional responsiveness and adaptability to meet demanding speed requirements.

- Unitecho

- China

- 90days

- 300

- Information

LED visual inspection equipment Specification

| Equipment technical parameters table | |

|---|---|

| Detecting element | LED |

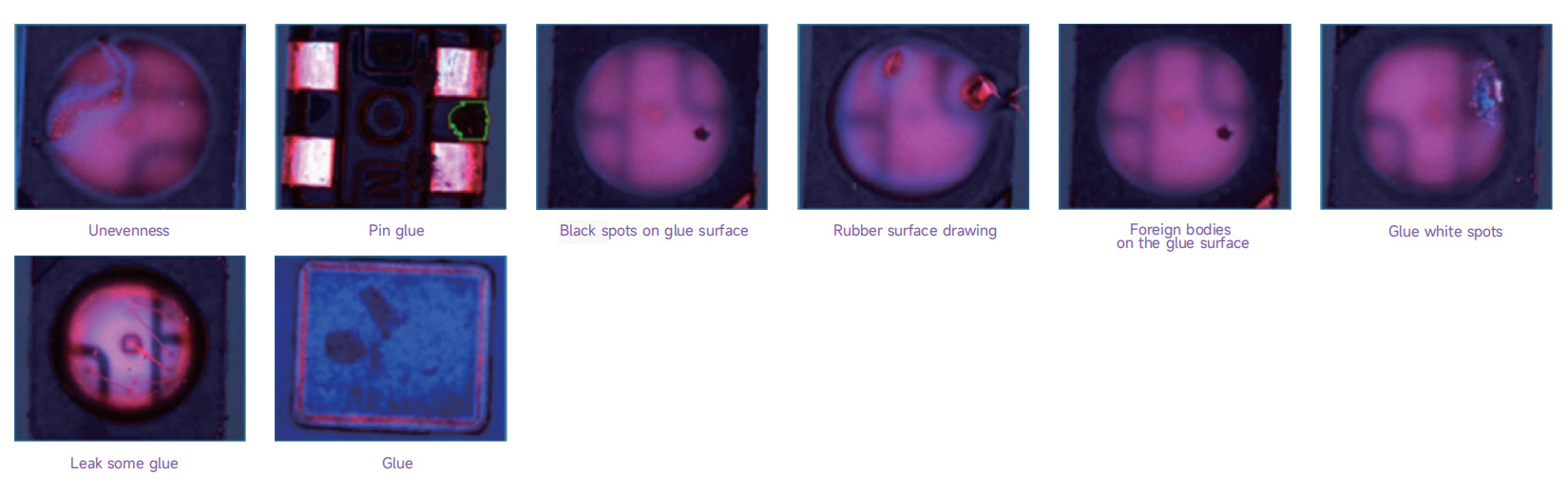

| Test item | Uneven, rubber feet, black spots on rubber surface, drawing on rubber surface, foreign bodies on rubber surface, etc |

| Detection station | 6-side detection |

| Detection sorting | 4 bins(customizable)OK*1, NG*2, Undetected*1 |

| CCD | 0.4M Pixels, USB3.0 Vision, Color*6, Sony CMOS |

| Illuminant | High brightness dual color dual channel |

| Resolution | 2.3 μm pixels,3.45 μm pixels,4.6 μm pixels,6.9 μm pixels |

| Speed | Max 290fps |

LED visual inspection equipment description

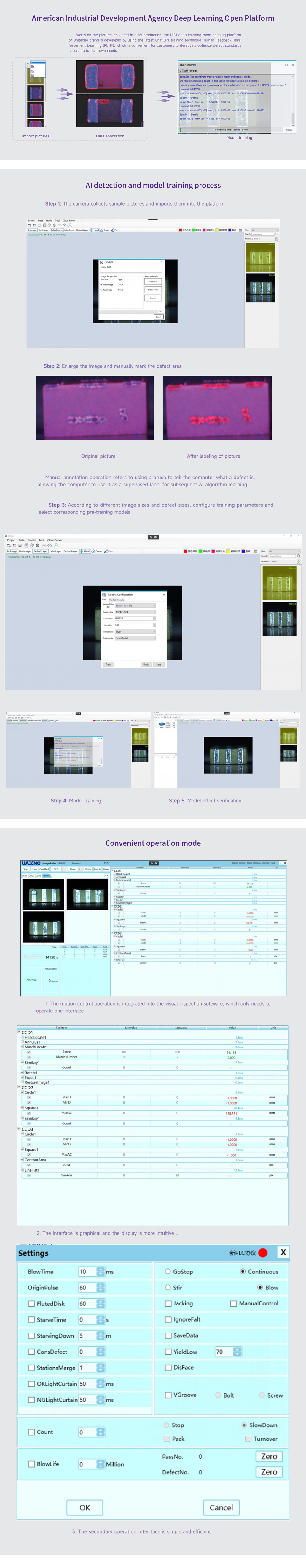

LED Visual Inspection Equipment is a cutting-edge, high-resolution inspection system designed to enhance the precision and efficiency of manufacturing processes. Equipped with state-of-the-art LED lighting technology, this device provides bright, illumination for clear image capture. The system typically consists of a camera, either color or monochrome, coupled with advanced algorithms that analyze visual data in real-time.

It captures images of products during various stages of production, detecting defects such as scratches, discoloration, or irregular shapes with exceptional accuracy. By integrating machine learning capabilities, it continuously learns to recognize patterns and adapt to different product variations, reducing the need for manual intervention. This smart inspection system not only improves product quality control but also saves time and resources by enabling early detection and automatic sorting.

LED Visual Inspection Equipment streamlines quality management, making it an indispensable tool for industries like electronics, automotive, and packaging, ensuring compliance with strict standards and maintaining customer satisfaction. As a result, it has become an increasingly popular choice for businesses seeking to optimize their inspection processes and maintain a competitive edge in the global market.

LED visual inspection equipment feature

The high-speed acquisition module is a powerhouse of real-time data capture, featuring lightning-fast sensors and processing capabilities that swiftly collect and analyze information, enabling businesses to make instantaneous decisions based on accurate and comprehensive data.

The high-speed processing module, on the other hand, acts as a digital brain, harnessing the power of high-performance computing to analyze and manipulate vast amounts of data at incredible speed, facilitating instant insights and optimized workflows in real-world applications.

The high-speed sorting system combines with the real-time control system to form an intelligent logistics solution. It efficiently sorts items at breakneck speeds, relying on sophisticated algorithms and automation, ensuring seamless and immediate decision-making, thereby enhancing overall efficiency and productivity within logistics operations.

LED visual inspection equipment

LED visual inspection equipment Defect Detection Case