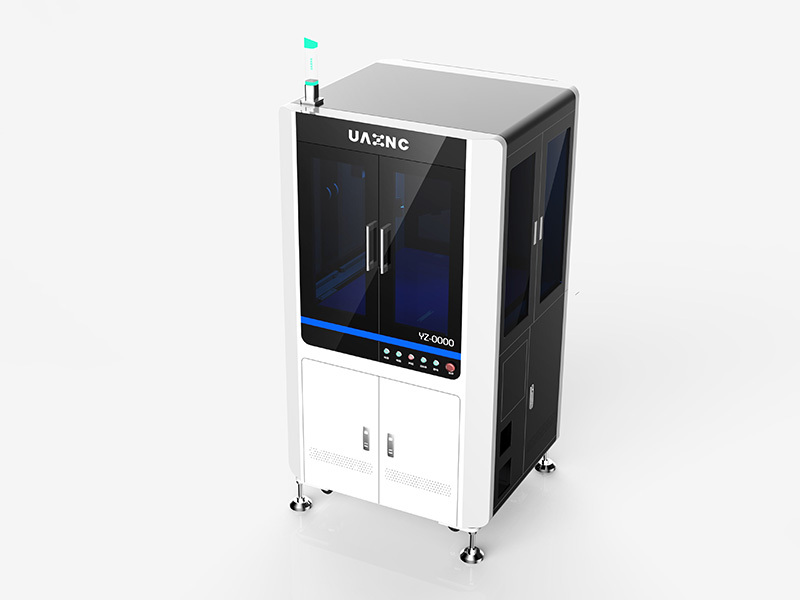

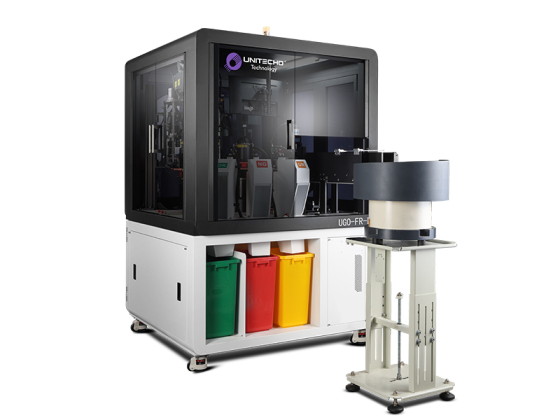

Optical Image Screening Machine

Advanced AI-powered inspection device detects defects in real-time with high-resolution cameras, machine learning, customizable settings, and environment-adaptability, enabling efficient & remote monitoring.

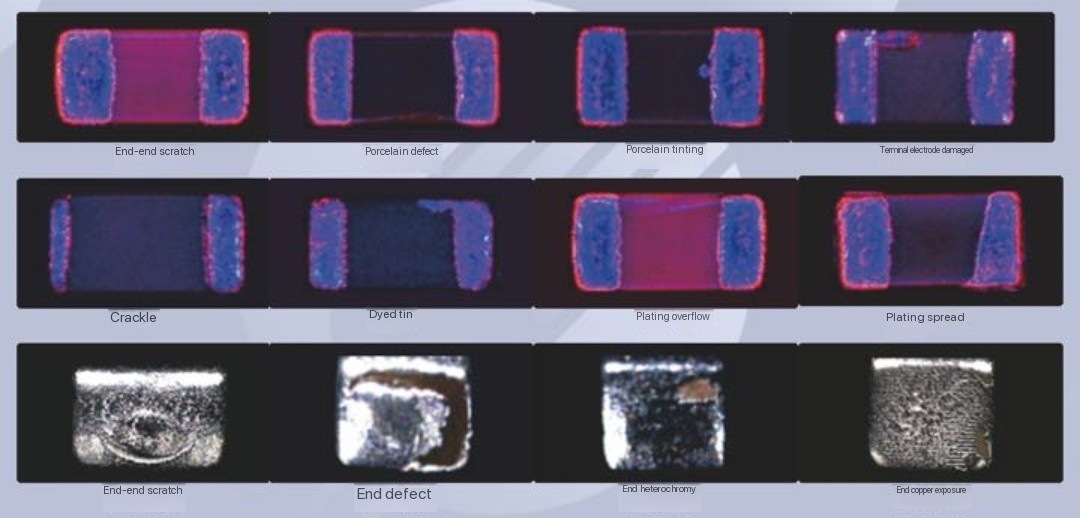

Inspection items: electrode size, ceramic dimensions, scratch marks, cracks, chipping, discoloration, and fissures.

- Unitecho

- China

- 90days

- 300

- Information

Optical Image Screening Machine advantage

The six-sided inspection device, powered by advanced AI technology, boasts a series of cutting-edge features that redefine precision and efficiency in visual inspection. Its key highlights include:

High Resolution Imaging: Equipped with high-resolution cameras, it captures minutest details with exceptional clarity, enabling accurate identification of even the smallest defects.

Machine Learning Capabilities: Utilizing deep learning algorithms, the device learns from vast datasets to continuously improve its detection accuracy, reducing human error and increasing throughput.

Intelligent Object Detection: The device employs object recognition software to swiftly distinguish between various components and patterns, streamlining the inspection process.

Real-Time Analysis: Thanks to its real-time processing capabilities, any anomalies are flagged immediately, ensuring rapid response and preventing potential quality issues.

Customizable Inspections: Users can configure the system to cater to specific industry standards or product specifications, making it adaptable to diverse manufacturing environments.

Environment-Adaptive: It functions effectively in varying lighting conditions and can adjust to different angles, ensuring consistent performance across different scenarios.

Remote Monitoring and Connectivity: The device is connected wirelessly, allowing for remote monitoring and data analysis, facilitating remote maintenance and enhancing overall productivity.

This AI-driven inspection equipment is a game-changer in the industrial landscape, delivering precision, speed, and adaptability to meet the most demanding quality control requirements.

Optical Image Screening Machine Detectable subject

Defect Effect Case Study: Multi-Layer Ceramic Capacitor (MLCC)