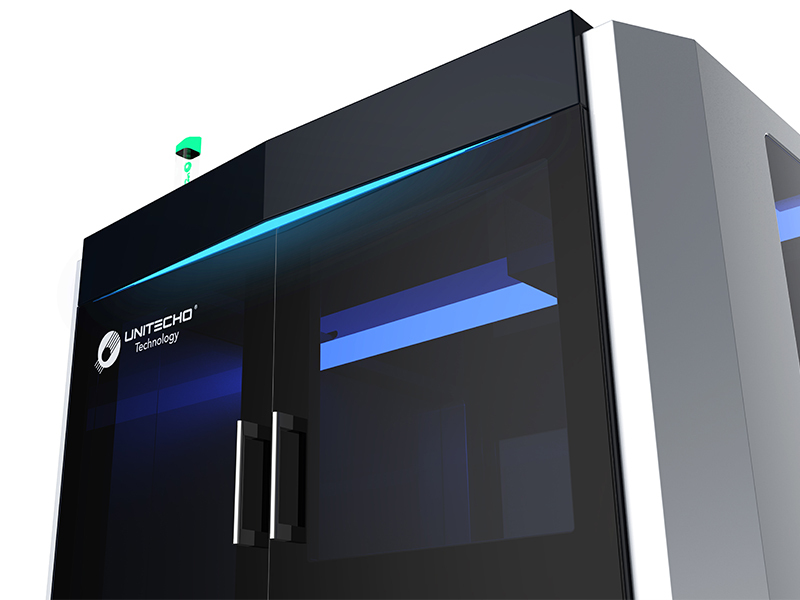

High Precision Optical Sorter

Crafted for precision, this cutting-edge technology rigorously scrutinizes each component, ensuring that it meets rigorous quality standards through meticulous inspections. Equipped with sensors and proprietary software, the machine flawlessly identifies defects, confirms precise dimensions, and produces flawless surfaces. Designed to excel in handling a wide range of components, this system delivers unparalleled reliability and efficiency.

- unitecho

- China

- 30 days

- 300

- Information

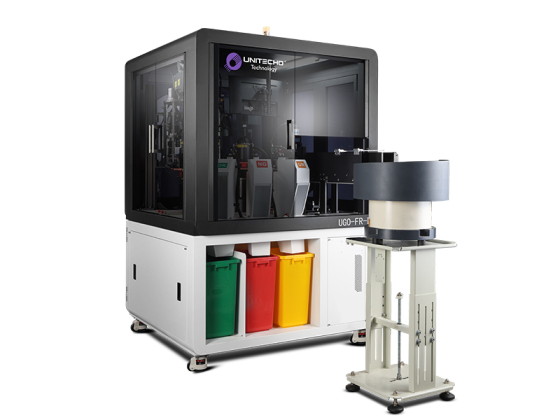

High Precision Optical Sorter Parameter

| Parameter | Specification |

|---|---|

| Overall Size | 1280x1280x2100 mm |

| Frame Material | One-piece molding, surface coating/painting |

| Gross Weight | 700 kg |

| Communication | Network ports - OPC/WebAPI, TCP/IP, SQLServer |

| Voltage | 220V / 50Hz |

| Pressure Range | 0.5 - 0.8 MPa |

| Detection | Diagonal, head size, ID/OD, shaft, cracks, tooth damage, dents, etc. |

| Detection Speed | <800 pieces/min |

| Software System | In-house developed |

| Detection Accuracy | ±0.002 mm |

| Cameras | Basler, Hikvision |

| Loading System | Vertical loader, incline conveyor, storage bin |

| Optical Plate | Diameter 800mm, thickness 8mm, high transparency, high precision |

| Industrial PC | Industrial computer |

| Outlets | 3-6 receiving boxes (customizable) |

High Precision Optical Sorter description

This device is an innovative visual inspection system designed for controlling the dimensions and surface finish of circular and other shaped components. It is capable of high-precision inspection of sealing parts, such as rubber and plastic materials, within its field of view. The system employs a series of workstations equipped with digital industrial cameras to examine parts for defects, and the captured images are transmitted non-destructively and without interference to a PC managed by a real-time operating system. This PC handles image processing and interaction with operators through a user-friendly interface.

The real-time system boasts exceptional system stability and incredibly fast control rates. Upon acquiring images and detailed post-processing, components are classified into distinct piles based on pass/fail criteria, either for reprocessing or for separate storage. The quick replacement process is facilitated by the short downtime, thanks to the saved configuration parameters and rapid cleaning of the machine and loader.

High Precision Optical Sorter Detectable object