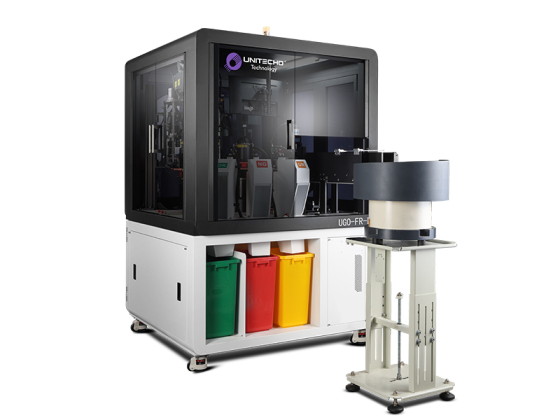

Fully Automatic Optical Sorting Machine

1. Non-contact measurement: This ensures minimal or no damage to both the observer and the observed subject, enhancing system reliability.

2. Broad spectral response: Capable of utilizing wavelengths beyond human sight, such as infrared, thus expanding the perceptual range for tasks that would otherwise be invisible to the naked eye.

3. Long-term stability: Unlike humans, who may tire or lose focus over extended periods, machine vision can consistently perform measurement, analysis, and recognition tasks for extended durations.

4. Savings in labor resources: By employing machine vision solutions, companies can significantly reduce manual labor, translating into substantial cost savings and efficiency gains.

- unitecho

- China

- 30 days

- 300

- Information

Fully Automatic Optical Sorting Machine Application Scope

The fully automatic optical inspection and sorting machine is a high-tech project designed for a wide range of applications, primarily in the sorting of metal and non-metal components such as hardware, plastics, etc.

1. Metal processing, assembly, and testing: This includes precise machining, assembly, and inspection of critical parts and specialized metallic materials.

2. Non-metal processing, assembly, and testing: The machine is applicable to non-metallic materials as well.

3. Electrical systems installation, calibration, and testing: It is utilized for handling the setup, testing, and verification of electrical systems.

4. Impact of software monitoring systems on inspection and sorting efficiency: The machine relies on advanced software to optimize its performance in terms of efficiency.

Due to the complexity of its detection processes, an optical sorting machine must possess high-performance image acquisition, data processing capabilities, and smooth operation. Consequently, its development presents a significant challenge, requiring a large pool of skilled researchers and substantial financial support.

Fully Automatic Optical Sorting Machine Work Process

The fully automatic optical sorting machine employs fundamental principles of electronic and optical technology to capture images of products, enabling rapid inspection of dimensions, surface defects, and missing components. Its high precision and speed make it a popular choice among component manufacturers. Thanks to its extensive applicability, it can significantly reduce investment costs for numerous companies while rigorously ensuring quality control.

Products are conveyed to a glass plate by a vibrating feeder. The glass's transparency, combined with optical hardware and a sophisticated image processing system from our in-house development, facilitates defect detection on the product surface. Optical glass disks serve as both carriers for product testing and transportation.

The machine utilizes up to 10 high-performance industrial cameras operating simultaneously to inspect the products, providing a 360-degree inspection without blind spots. Our proprietary high-speed image processing system enables swift detection at rates of up to 9,000 pieces per hour. Post-inspection, multiple output mechanisms sort products based on different specifications or types of defects, resulting in efficient categorization.