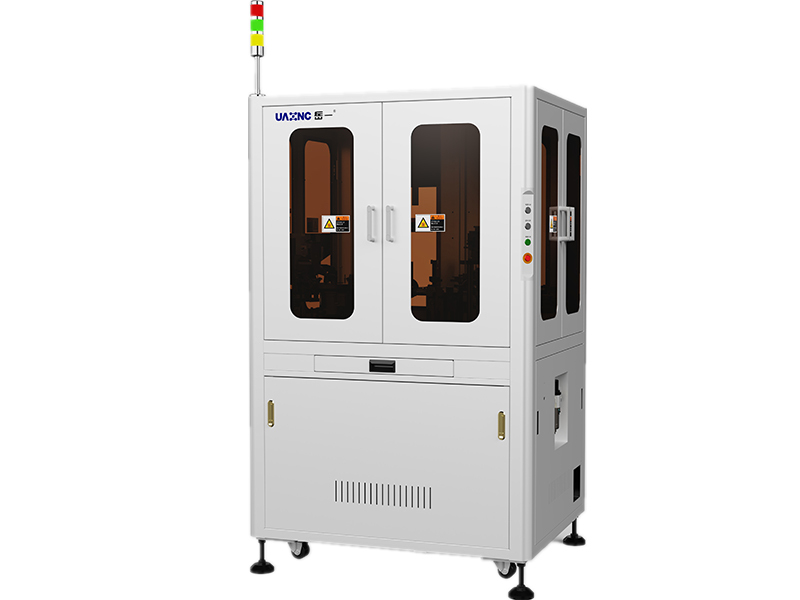

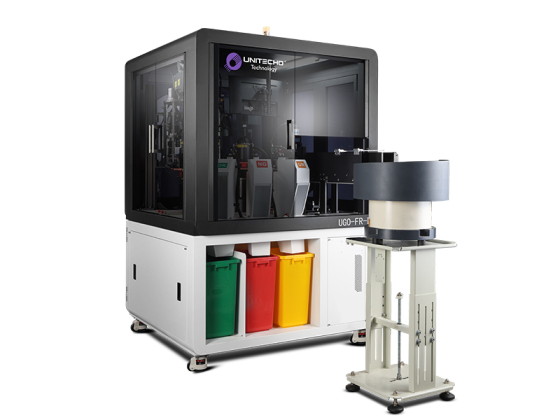

Automatic Screw Bolt Sorter Glass Plate Optical Sorting Machine

1. Enhanced Efficiency: The Automatic Screw Bolt Sorter boasts exceptional speed and precision, processing a wide variety of screws and bolts with minimal human intervention, significantly boosting productivity in manufacturing.

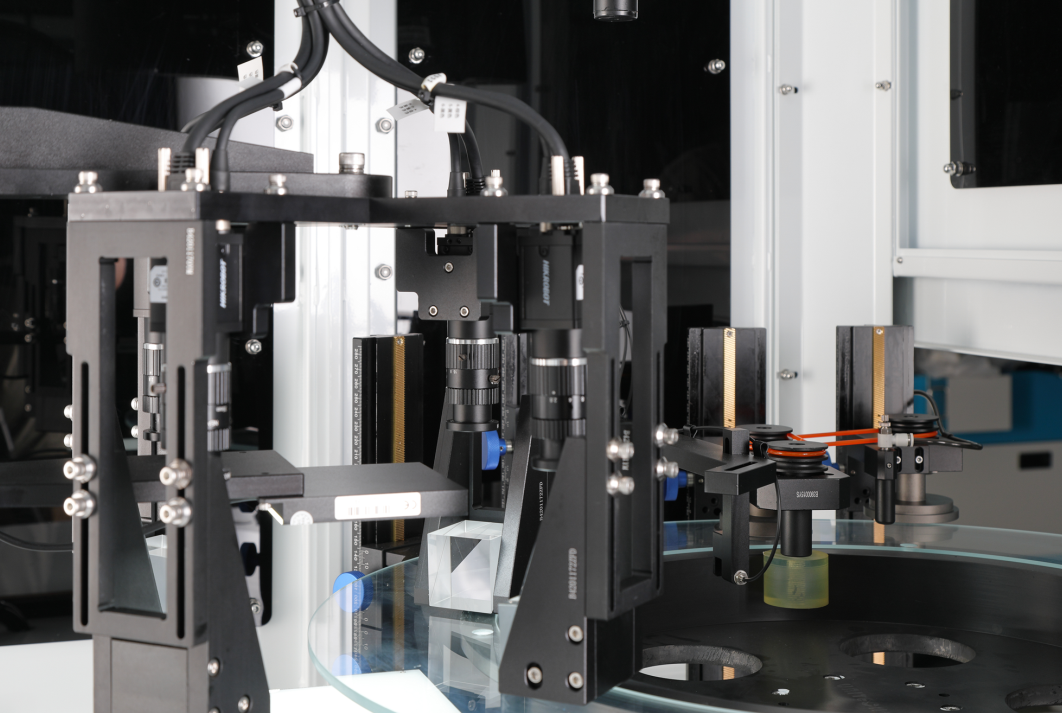

2. High Accuracy: Equipped with advanced optical sensors, the machine ensures precise separation based on screw head shape, thread pitch, or material quality, minimizing errors and wastage in the assembly line.

3. User-Friendly Design: A simple glass plate interface allows for easy monitoring and maintenance, facilitating quick adjustments to accommodate different bolt types, making it an adaptable solution for diverse industrial applications.

4. Energy Efficiency: Optimized for energy consumption, the glass plate optical sorter reduces energy costs by minimizing machinery downtime and utilizing smart automation technologies, promoting sustainable manufacturing practices.

- Unitecho

- China

- 15days

- 3000

- Information

Automatic Screw Bolt Sorter Glass Plate Optical Sorting Machine description

As domestic industries advance and upgrade, there is an increasing demand for thorough inspection of high-precision components such as automotive and electronic screws. Human visual inspection, conducted for extended periods, often results in fatigue, decreased efficiency, and inconsistent quality. By leveraging machine vision, the reliance on manual eyesight can be significantly replaced, leading to significant improvements in production speed and inspection accuracy. This approach not only reduces customer complaints due to fewer defects but also lowers labor costs, streamlining the manufacturing process.

Automatic Screw Bolt Sorter Glass Plate Optical Sorting Machine application

The Automatic Screw Bolt Sorter Glass Plate Optical Sorting Machine, an innovative piece of industrial equipment, finds extensive applications in various sectors where precision and automation are critical. Primarily designed for the electronics, automotive, and assembly industries, this machine serves several purposes:

1. Electronics Manufacturing: It efficiently sorts screws and bolts based on size, shape, and thread specifications, ensuring the correct fit for electronic assemblies, preventing malfunctions and enhancing product reliability.

2. Aerospace Industry: The machine helps in organizing fasteners for aircraft maintenance and new builds, saving time and reducing the risk of assembly errors.

3. Automotive Industry: It plays a pivotal role in automating the assembly line by segregating screws for different vehicle parts, ensuring consistent and high-quality assembly processes.

4. Machinery Manufacturing: In factories producing heavy machinery, the sorter ensures that correct bolts and screws are utilized during installation, reducing downtime and increasing productivity.

5. Quality Control: It streamlines quality control by separating defective or mismatched components, reducing the need for manual inspection and minimizing waste.

6. Inventory Management: By accurately classifying screws, the machine aids in maintaining inventory efficiently and prevents stockouts or overstocking.

Automatic Screw Bolt Sorter Glass Plate Optical Sorting Machine is a versatile solution that optimizes manufacturing workflows, improves product consistency, and contributes to overall operational efficiency and cost savings.