The working principle of an external appearance inspection device

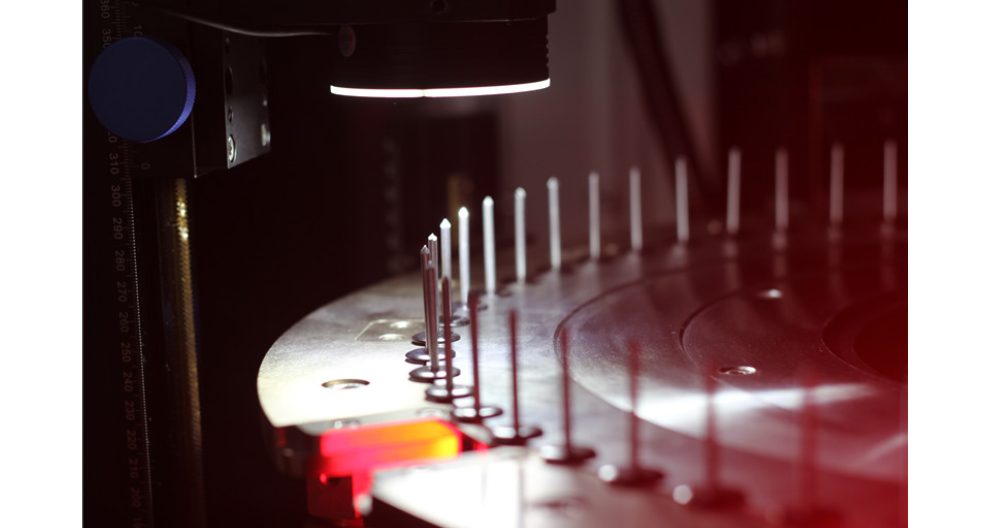

2024-11-10 15:48The working principle of an external appearance inspection device relies on image analysis from industrial cameras. It customizes functional tests for various defects, such as polarity issues, misaligned edge seals, leakage, unbuckled edges, open seals, non-circular seals, bulges greater than 0.2mm, faulty caps, incorrect specifications, bad soldering points, color inconsistencies, and missing pins. Size detection involves checking dimensions like length, width, height, thread diameter, and specific local requirements.

This device addresses common challenges in industries, like the need for manual inspection of numerous products, slow speed, and high likelihood of missed defects. By understanding industry-specific requirements, it streamlines the process, reducing human error caused by fatigue or variation in quality control.

It's often assumed that higher camera specifications guarantee better precision, but precision is also influenced by lighting and lens quality. In reality, investing in appropriate lighting and lenses can meet most routine inspection needs without overkill. Optical sorting machines must be versatile enough to handle the diverse production methods and size variations in the fasteners industry, where a single machine capable of detecting multiple product sizes is a valuable investment.

When it comes to identifying defects like head cracks, compression damage, clogged threads, or deformations, effective lighting design plays a crucial role. By tailoring light sources to product characteristics, the reflection patterns guide the camera to easily detect these issues. Over the years, visual inspection equipment has gained popularity due to its efficiency, intelligence, and non-destructive nature, gradually replacing manual inspections across industries.