MLCC (Multi-Layer Ceramic Capacitor) and LTCC (Laminated Thin Film Chip Capacitor) Case

MLCC (Multi-Layer Ceramic Capacitor) and LTCC (Laminated Thin Film Chip Capacitor) Case Studies:

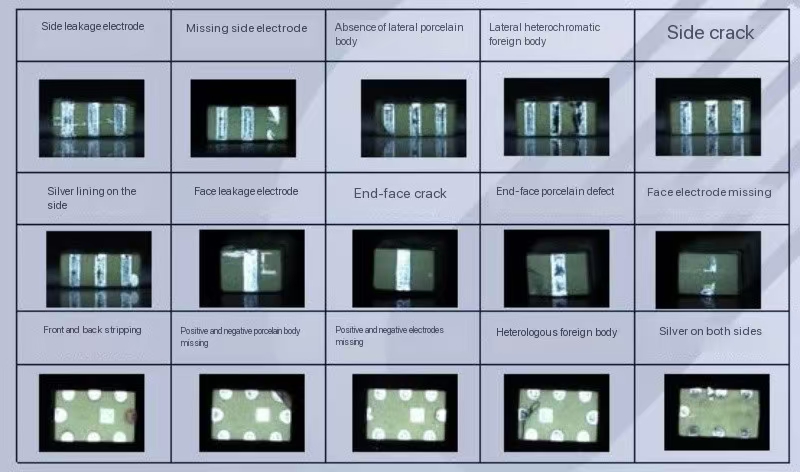

In the realm of electronic components, our advanced detection systems shine brightly when it comes to MLCCs and LTCCs. For MLCCs, we have successfully implemented solutions that catch early signs of defects like variations in capacitance, delamination, cracking, and compromised electrical insulation. Our technology ensures that only premium-quality capacitors make it to the market, preventing potential malfunctions in circuits.

In the case of LTCC, where precision is paramount, our inspection platforms are capable of detecting minuscule issues such as misalignment of thin film layers, dielectric cracks, and surface contamination. These capabilities help manufacturers identify defective dies before assembly, saving costs and improving yield rates. A prominent example is the reduction in assembly yield losses for a leading electronics manufacturer, which saw a significant improvement in the consistency and reliability of their LTCC-based products after integrating our inspection solution.

By working closely with leading MLCC and LTCC producers, we have not only streamlined their quality control processes but also enhanced their competitive edge in the global market. Our expertise and commitment to precision demonstrate how effective detection systems can revolutionize the electronics manufacturing landscape.