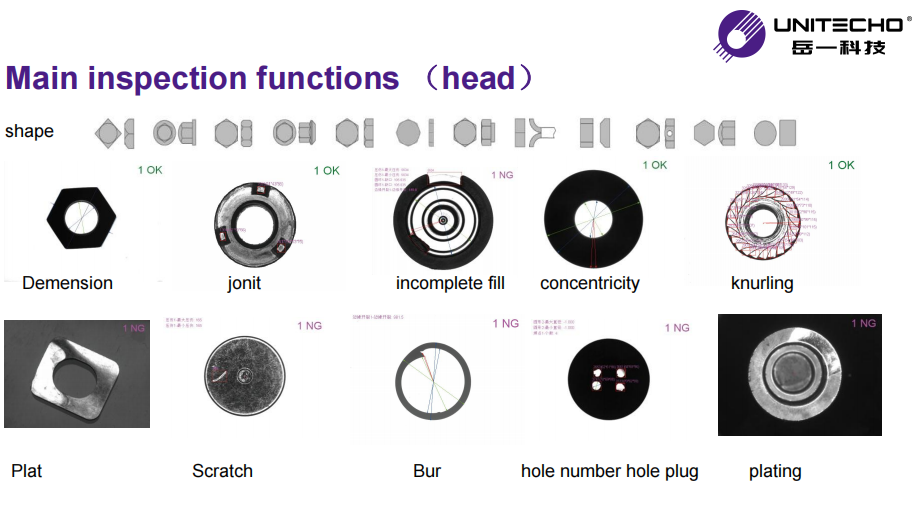

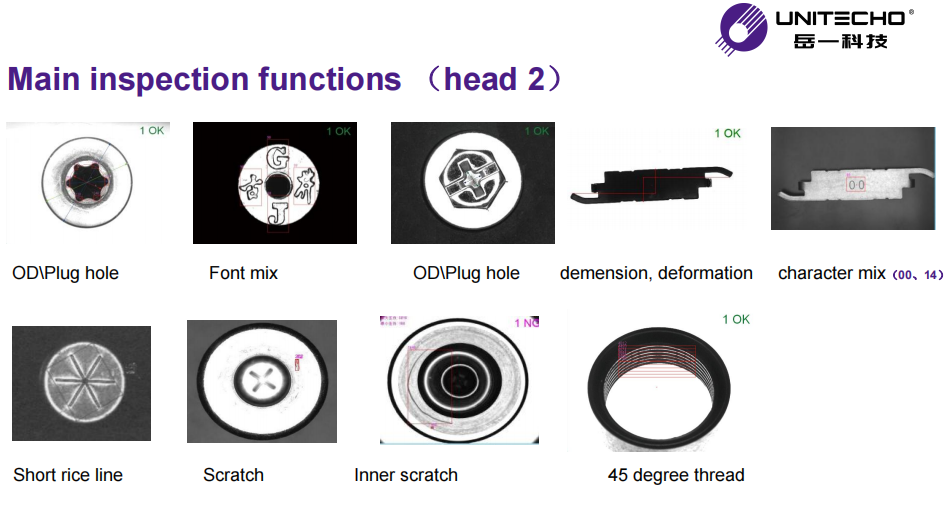

Main inspection functions of optical sorting machine

Our innovative inspection equipment showcases exceptional prowess in detecting a myriad of critical issues that can compromise the performance and aesthetics of electronic components. In the case of capacitors, our systems excel at identifying defects such as chipped paint, solder bridging, contamination, illegible markings, dimensional irregularities, misaligned lids, missing electrodes, excess or insufficient adhesive, and even cosmetic deformations.

When it comes to semiconductor chips, our technology is equally adept at pinpointing potential problems, including missing or misplaced components, glass contamination like micro-cracks or chips, fractures, delaminated layers, dirt buildup, and any kind of physical damage. These capabilities enable our clients to maintain stringent quality standards, minimizing production risks and ensuring the consistent delivery of top-notch products.

Illustrating these achievements, numerous industry leaders have entrusted us with the vital task of safeguarding their brand image and end-users' experience through efficient and accurate testing. By partnering with us, they have witnessed improved product yields, reduced downtime, and a significant boost in overall process efficiency. Our dedication to precision and reliability sets us apart as a go-to solution for high-tech manufacturing environments worldwide.