Semiconductor Passive Components Optical Sorting Solution

- Home /

- Semiconductor Passive Components Optical Sorting Solution

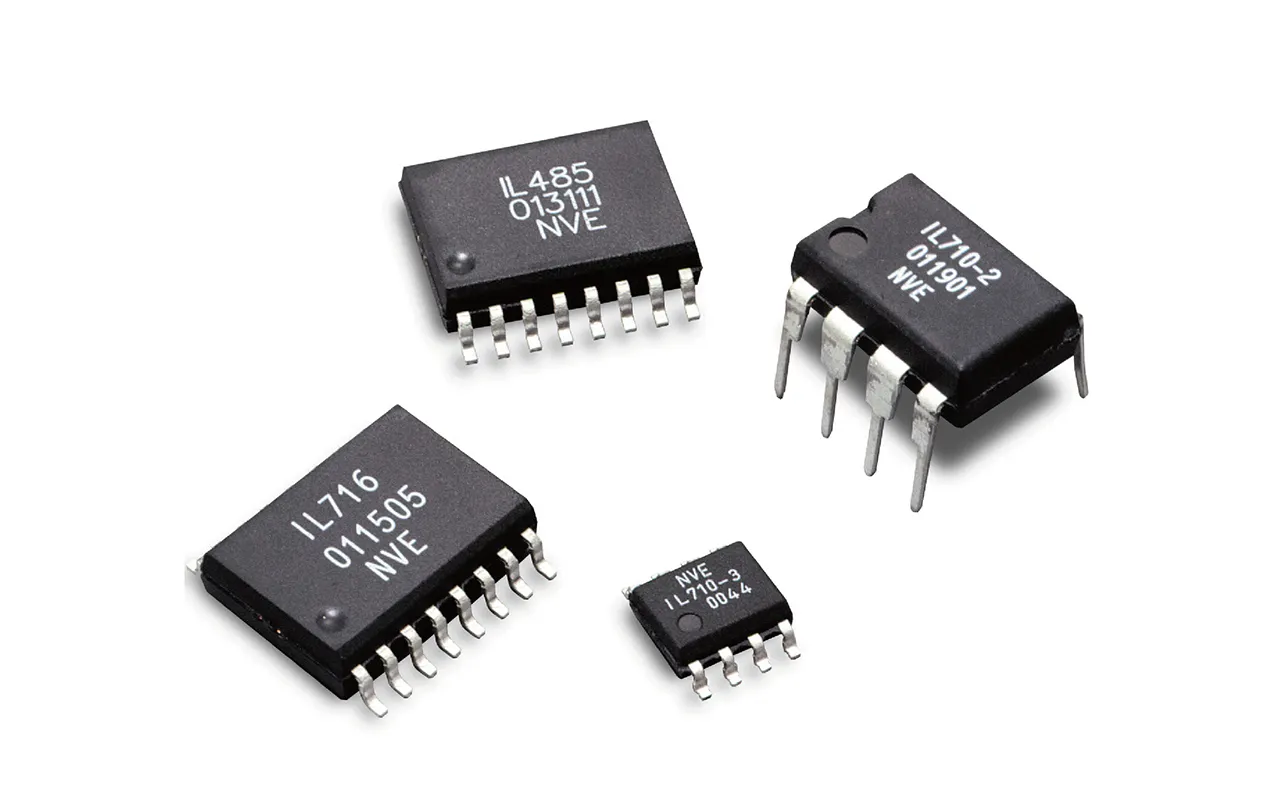

Precision Inspection for Semiconductor Passive Components

UNITECHO provides specialized AI-powered visual inspection solutions for passive components, ensuring every MLCC, resistor, capacitor, and inductor meets the highest standards of precision and electrical performance. Our systems perform high-speed, non-contact inspections to detect critical defects such as electrode peeling, body chipping, surface scratches, dimensional deviations, and foreign material contamination.

We use advanced glass plate sorting tech and AI to ensure top-notch quality control for making lots of tiny parts. Our system easily fits into production lines, sorts parts in real-time, and counts them super accurately. It stops bad or mixed parts from moving forward, gets rid of manual sorting mistakes, boosts output, and makes electronic parts more reliable. This helps semiconductor makers hit their zero-defect goals.

Tailored Solutions by Product

Optical Sorting Machine

Tailored for passive components like MLCCs and chip resistors, our Glass Plate and Six-sided sorting machines provide high-speed, non-contact inspection. They utilize AI-driven algorithms to detect micron-level defects such as electrode damage, body cracks, and chipping that affect electrical performance. This ensures zero-defect quality by automatically separating non-conforming parts from the production stream with exceptional speed and reliability.

Optical Counting Machine

Replacing traditional weighing methods, our high-precision optical counting machine offers 100% accuracy for fragile bulk components like capacitors and inductors. Its non-contact design eliminates static damage risks and prevents physical stress on the components often caused by vibration plates. This is essential for high-value inventory management, ensuring the exact quantity is processed without the errors caused by unit weight variations.

Relevant Introduction

Optical Sorting Machine

Optical Sorting Machine

Optical Measuring Machine

Optical Measuring Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Packing Machine

Integrated with visual counting technology, our automated packaging solutions are specialized for the anti-static bagging of sensitive passive components. From pre-made pouches to final kitting, they ensure precise quantity control and contamination-free sealing. This streamlines the backend supply chain, preventing static discharge damage and ensuring ready-to-ship quality for the global semiconductor market.

Relevant Introduction

Optical Sorting Machine

Optical Sorting Machine

Optical Counting Machine

Optical Counting Machine

Packing Machine

Packing Machine

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

uidi@unitecho.com

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province

Industry Insights & Resources