Software Advantages

Intuitive Touch Screen Control

Features an advanced, user-friendly touch screen interface that simplifies machine operation, allows for quick parameter adjustments, and makes troubleshooting more efficient.

All-in-One Process Integration

Seamlessly combines bag-making, sealing, cutting, and optional printing into a single, continuous automated process. This integrated functionality significantly saves time and reduces operational costs.

Optimized Design for Easy Maintenance

Engineered with an optimized mechanical structure that is designed for convenient disassembly and cleaning, helping to minimize downtime and simplify routine maintenance tasks.

Independent Temperature Control for Sealing Versatility

Equipped with separate temperature regulators for both the horizontal and vertical seals. This allows for precise control to achieve strong, reliable seals across a wide variety of packaging film types and thicknesses.

Usage Scenarios

Automotive Fasteners

Perfect for bagging various quantities of screws, bolts, and nuts. The machine's ability to create bags from film rolls significantly reduces material costs compared to pre-made bags, offering a cost-effective solution for kitting and assembly line supply.

Automotive Stamping Parts

Ideal for packaging small-to-medium stamped parts like clips, brackets, and washers. The automated process ensures high-speed bagging, keeping components organized and protected from loss or damage during in-plant logistics.

Automotive Plastic Parts & Structural Components

Efficiently packages injection-molded plastic clips, interior fasteners, and other small structural parts. The adjustable bag length accommodates a wide variety of part sizes, minimizing film waste and maximizing flexibility.

Automotive Rubber & Sealing Components

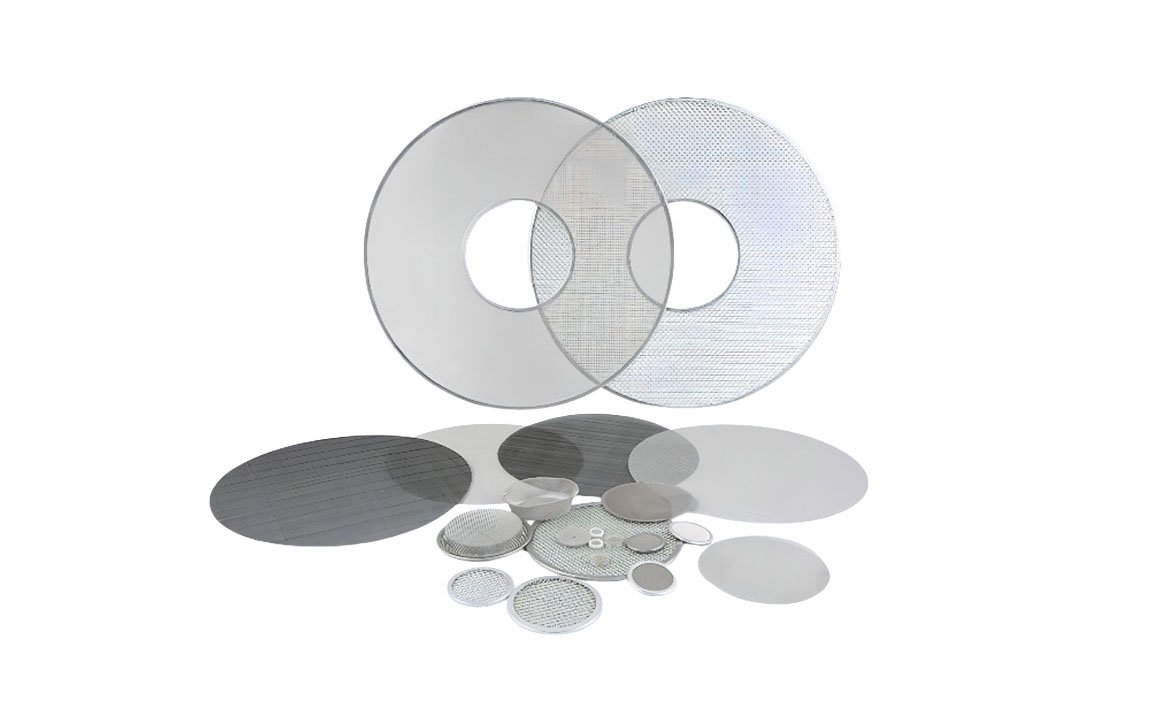

Excellent for the bulk packaging of O-rings, gaskets, and small seals. The sealed bags keep the components clean, prevent them from drying out, and simplify inventory management for assembly.

Electronics Metal Hardware

Perfect for creating accessory kits with micro-screws, nuts, and standoffs. It can be integrated with counting systems to produce accurately filled, sealed bags ready for inclusion in final consumer product packaging.

Electronics Plastic Parts

Provides gentle, protective packaging for cosmetic plastic parts such as buttons, keycaps, and small housings. The smooth film material and secure seal help prevent surface scratches and dust contamination during transport.

Electronics Micro-precision Parts

Efficiently handles the bulk packaging of lightweight micro-components like tiny springs, contacts, and connectors. The automated bag-making process is ideal for high-volume, low-cost packaging required in electronics manufacturing.

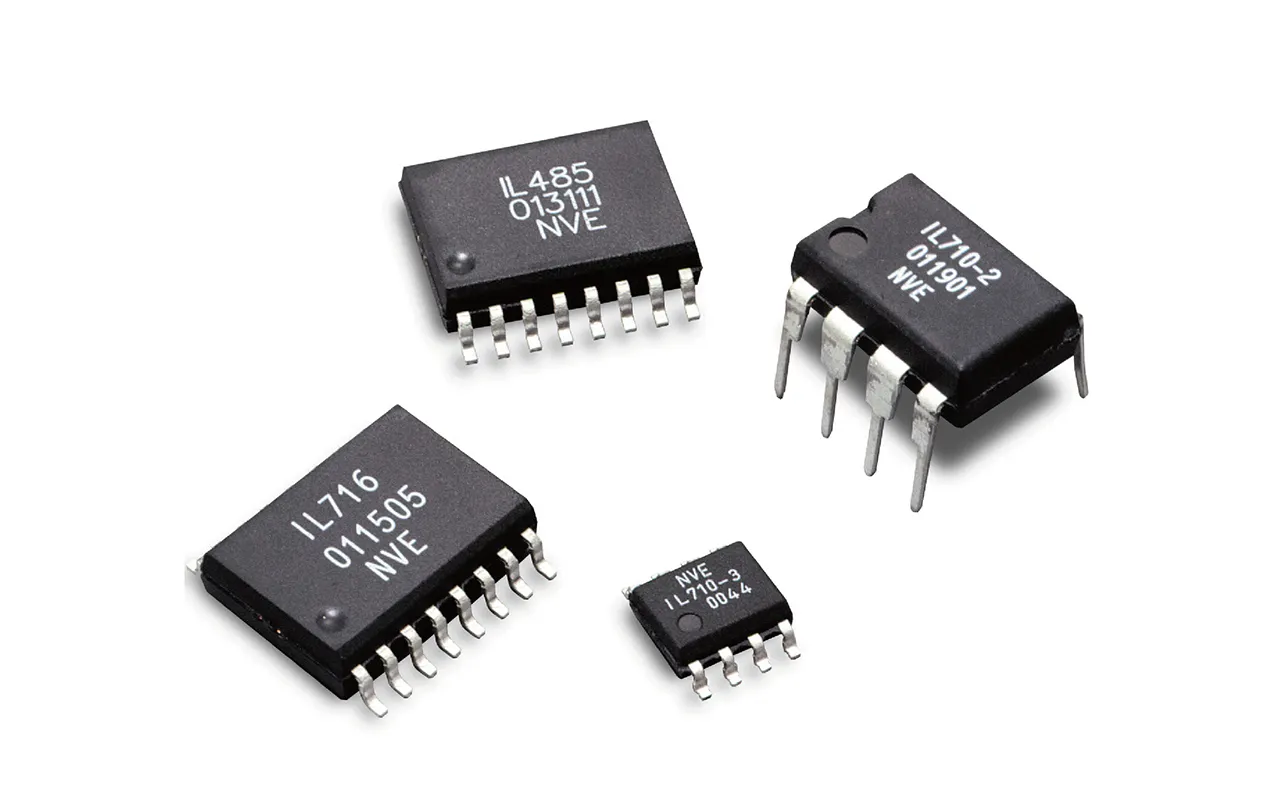

Semiconductor Interconnects

Delivers essential dust-proof packaging for bulk connectors, pins, and terminals. The machine is compatible with anti-static (ESD) film, providing critical protection against electrostatic discharge for sensitive components.

Semiconductor Passive Components

Ideal for the cost-effective bulk bagging of robust passive components like larger capacitors, resistors, and inductors. Its high-speed, automated process is perfectly suited for managing large production batches for distribution.

Medical Injection Molding Consumables

Suitable for the bulk, non-sterile packaging of plastic consumables like vial caps, connectors, or casings. It provides a low-cost, automated solution for protecting and organizing parts before they enter final assembly or sterilization processes.

Military Precision Fasteners

Creates durable, sealed packages for mission-critical fasteners. Using appropriate barrier film, it provides robust protection against moisture and environmental factors, making it ideal for long-term storage and field maintenance kits.

Ammunition Components

A high-efficiency solution for packaging non-sensitive ammunition components like empty casings, links, or projectiles in bulk, streamlining the process of organizing and protecting parts for subsequent assembly stages.

Product Parameters

| Equipment Model | PL320 | PL420 | PL520 | PL620 |

|---|---|---|---|---|

| Bag-making Dimensions | (W) 50-150mm (L) 60-250mm | (W) 60-200mm (L) 60-300mm | (W) 80-250mm (L) 80-350mm | (W) 100-300mm (L) 100-400mm |

| Packaging Speed | 0-20Bags/min | 0-20Bags/min | 0-15Bags/min | 0-15Bags/min |

| Applicable Power Supply | 220V~50-60Hz, 3.0KW | 220V~50-60Hz, 3.0KW | 220V~50-60Hz, 5.0KW | 220V~50-60Hz, 5.0KW |

| Compressed Air | 6-8kg/cm², 0.3m³/min | 6-8kg/cm², 0.3m³/min | 6-8kg/cm², 0.4m³/min | 6-8kg/cm², 0.4m³/min |

| Overall Machine Weight | 400kg | 450kg | 500kg | 600kg |

| Overall Machine Dimensions | 1450*1000*1400mm | 1450*1100*1500mm | 1600*1300*1700mm | 1800*1500*1900mm |

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province