Software Advantages

High-Efficiency V-Shaped Design

Features an innovative 8-channel V-shaped structure (expandable to 16, 24, or 32) that ensures rapid and flexible material flow. This design supports high-speed production lines, achieving counting speeds of up to 60 bottles per minute with smooth operation.

AI-Powered Precision Counting

Powered by UNITECHO’s proprietary Deep Learning AI algorithms and the UIDI training platform, the system guarantees an ultra-low error rate (≤ 1‰). It intelligently distinguishes overlapping items to ensure absolute accuracy in quantity control.

Broad Material Versatility

Engineered to handle a wide variety of industrial and medical materials, including fasteners (nuts, bolts), plastic parts, and pharmaceutical pills/capsules. The system adapts easily to high-bottle-speed and small-quantity counting requirements without complex re-tooling.

Intelligent Software Ecosystem

The system utilizes advanced pattern recognition to automatically detect the shape, position, and orientation of the workpiece. This eliminates the need for Backed by the comprehensive UIDG defect generation software and a massive industrial defect database, the system allows for rapid model construction. The user-friendly interface ensures that anyone can operate the machine easily, simplifying new product setup and data management.time-consuming alignment or expensive fixtures—simply place the part on the stage, and the software handles the rest.

Usage Scenarios

Automotive Fasteners

The multi-channel design offers high-speed counting for screws, bolts, and nuts, ensuring 100% quantity accuracy for packaging and assembly kits.

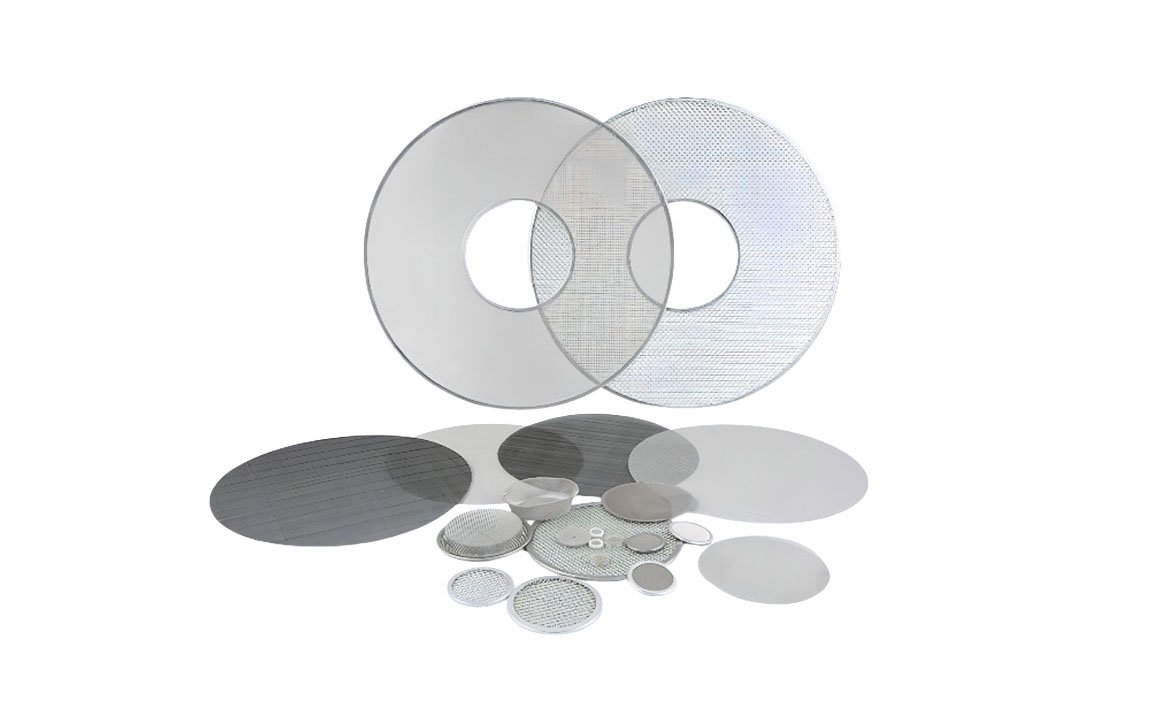

Automotive Rubber & Sealing Components

Ideal for counting O-rings and small gaskets. The non-contact vision system prevents deformation that often occurs with mechanical counters.

Automotive Precision Machined Parts

Accurately counts small pins, shafts, and connectors, eliminating "short-shipping" errors caused by unit weight variations in turned parts.

Electronics Micro-precision Parts

The perfect solution for micro-screws, springs, and tiny contacts. It automatically rejects foreign materials while delivering exact counts for accessory packaging.

Electronics Metal Hardware

Handles shielding cans and small metal brackets efficiently, replacing error-prone weighing scales for high-value inventory control.

Electronics Plastic Parts

Suitable for counting small plastic keys, buttons, and optical lenses without scratching their surfaces

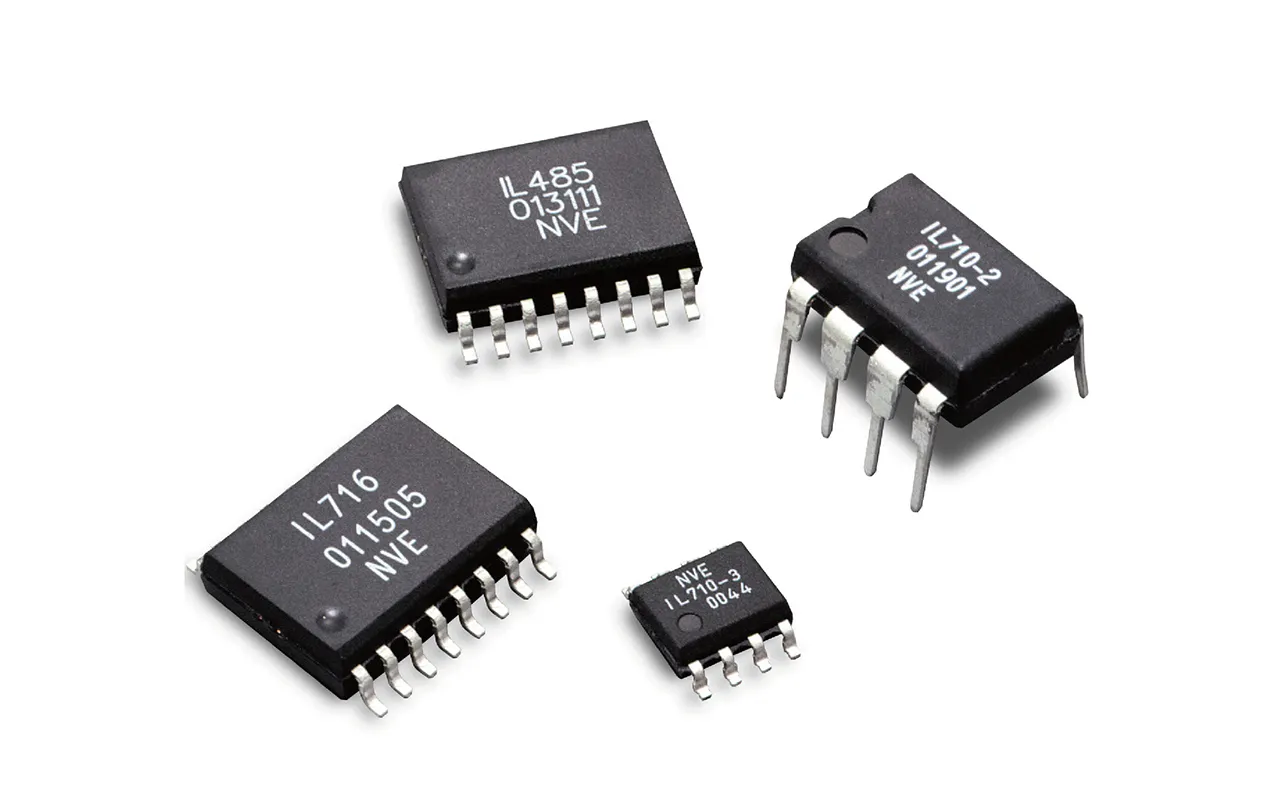

Semiconductor Passive Components

Designed for bulk MLCCs, resistors, and capacitors. The system eliminates static damage risks and ensures precise quantification for inventory management.

Semiconductor Packaged Devices

Offers non-contact counting for IC chips and discrete devices, preventing physical damage to leads and packages.

Semiconductor Interconnects

Accurately counts loose pins and terminals, ensuring the correct number of parts are prepared for bag-feeding packaging.

Medical Fasteners & Implants

Ensures absolute quantity accuracy for high-value titanium screws and bone nails, preventing costly shortages in surgical kits.

Medical Injection Molding Consumables

Provides hygienic, non-contact counting for sterile rubber stoppers and syringe caps, avoiding cross-contamination risks.

Medical Electronic Components

Safely counts delicate sensors and miniature electronics without physical stress, ensuring component integrity.

Military Precision Fasteners

Verifies the exact count of aviation screws and bolts for maintenance kits, eliminating Foreign Object Damage (FOD) risks from extra loose parts.

Ammunition Components

Safely processes small energetic components like primers and bullets. The non-contact vision technology significantly reduces physical impact risks compared to mechanical feeders.

Military Optoelectronic Components

Counts sensitive optical filters and small lenses without surface contact, preserving their optical performance.

Product Parameters

| Category | Details |

|---|---|

| The main technical parameters | - |

| Equipment Model | D835/D850/D890 |

| Counting Efficiency | 60 bottles/min ① |

| Counting Error | ≤ 1‰ ② |

| Total Power | 0.9KW |

| Power Supply | AC 220V±10% 50Hz±1% |

| Working Air Pressure | 0.5-0.8 MPa |

| Air Consumption | ≤ 1.0m³/min |

| Overall Dimensions | 【D835】L1067mm×W540mm×H1090mm |

| 【D850】L1930mm×W680mm×H1440mm | |

| 【D890】L2020mm×W980mm×H1374mm | Height includes feet |

| Total Mass | 160kg |

| Product Overview | D835/D850/D890 are multi-channel visual counting machines with two-stage vibrating plate feeding and multi-channel framework. They are suitable for counting small-quantity materials at high bottle speeds. All models can be expanded to 16, 24, or 32 channels according to customer needs to improve counting efficiency. |

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province