Software Advantages

High-Speed Line Scan CCD Technology

Equipped with an imported line array CCD sensor boasting 2048 resolution and a scanning speed of 10,000 times/second. Paired with a 6MP lens, it achieves theoretical 100% accuracy and can detect micro-particles as small as 0.3mm.

Smart "Quantity Combination" Mode

Utilizes a unique algorithm to combine counts from multiple hoppers, significantly maximizing packaging speed and precision. The integrated attitude adjustment board stabilizes falling materials, ensuring accurate recognition for complex geometries like gears and terminals.

Rapid Changeover & One-Key Cleaning

The industrial PC stores unlimited material parameters for instant recall via a user-friendly touch interface. The "One-Key Rapid Cleaning" function clears residual materials instantly, allowing for seamless transitions between different product batches with minimal downtime.

AI-Driven Safety & Anomaly Detection

Backed by UNITECHO’s intelligent software, the system features comprehensive alarm functions for foreign objects, material shortages, and packaging errors. It ensures strict quality control by preventing defective or incorrect counts from advancing in the production line.

Usage Scenarios

Automotive Fasteners

The Z875 processes high volumes of screws, bolts, and nuts. Its combination mode is perfect for kitting lines that require thousands of fasteners per hour without error.

Automotive Precision Turned Parts

Ideal for counting large batches of small pins and shafts where traditional weighing fails due to oil weight or material density variations.

Automotive Rubber & Sealing Components

Capable of high-speed counting for O-rings and seals, preventing deformation while maintaining the pace of automotive assembly lines.

Electronics Micro-precision Parts

The line scan technology accurately detects and counts micro-screws, springs, and contacts as small as 0.3mm, ensuring precise inventory for electronic assembly.

Electronics Metal Hardware

Efficiently handles bulk shielding cans and small metal brackets, ensuring the correct quantity is supplied to automated assembly stations.

Electronics Plastic Parts

Suitable for the rapid counting of small plastic buttons, keycaps, and fasteners used in consumer electronics.

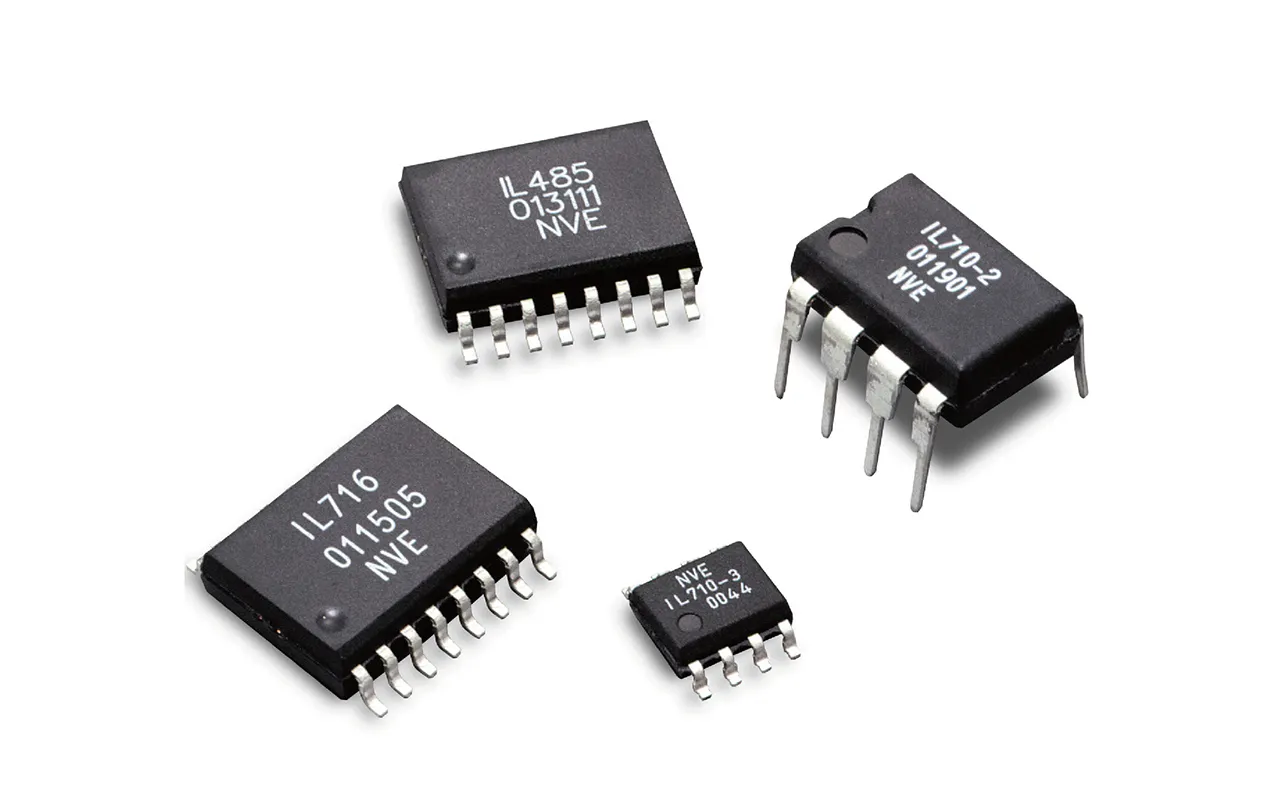

Semiconductor Passive Components

The machine's high speed (5000/min) makes it the ideal solution for bulk packing of MLCCs, resistors, and capacitors, eliminating static damage risks associated with vibratory bowl feeders.

Semiconductor Interconnects

Accurately counts loose pins and terminals for bag-feeding packaging, ensuring exact quantities for downstream connector assembly.

Medical Injection Molded Consumables

Provides high-speed, hygienic counting for disposable syringe caps, plungers, and rubber stoppers, meeting the high-throughput demands of medical manufacturing.

Medical Fasteners & Implants

Ensures 100% accurate counts for titanium screws and hardware, preventing shortages in surgical kits.

Ammunition Components

Safely and rapidly counts small energetic components like primers and bullets. The non-contact visual method significantly reduces physical impact risks compared to mechanical sorting.

Military Precision Fasteners

Verifies the exact count of aviation-grade rivets and screws, ensuring zero FOD risks and accurate logistics for military maintenance supplies.

Product Parameters

| Item | Specification |

|---|---|

| Equipment Model | Z875 |

| Counting Efficiency | 5000 grains/min ① |

| Counting Error | ≤ 1% ② |

| Total Power | 2KW |

| Power Supply | AC 220V±10% 50Hz±1% |

| Working Air Pressure | 0.5-0.8 MPa |

| Air Consumption | ≤ 1.0m³/min |

| Dimensions | L1333×W1070×H1564mm |

| Total Weight | 350kg |

| Product Overview | Z875 is a visual counting device, featuring vibratory feeder, multi-channel recognition, two-stage control, and high counting efficiency. |

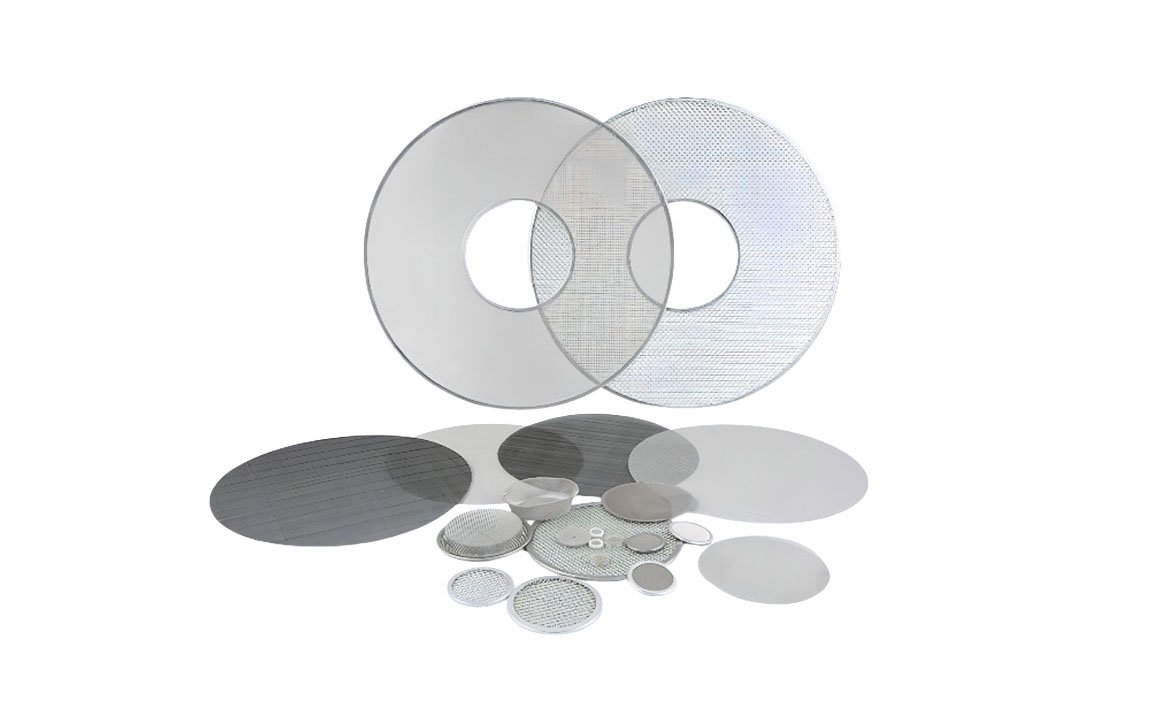

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province