Software Advantages

Comprehensive 360° Defect Detection

The UGO-EA-I employs both internal and external prism-based 360° inspection cameras combined with top/bottom appearance cameras using custom combined light sources. This multi-angle approach ensures complete surface coverage, detecting burrs, raw edges, flow marks, cracks, pitting, mold contamination, and foreign material inclusions that single-view systems miss.

AI-Accelerated Inspection Intelligence

Powered by UNITECHO's proprietary three-platform AI ecosystem—UZVISION visual platform, UIDI algorithm platform, and UIDG defect generation software—the system leverages an industrial-grade i7 computer with NVIDIA high-computing graphics card. The AI model database, built from over 3,000 industry customers and 1,000+ product types, enables rapid deployment with minimal sample training.

Precision Telecentric Measurement

Top and bottom size detection cameras utilize telecentric lenses to eliminate perspective distortion, ensuring accurate dimensional measurement across the entire 5-65mm outer diameter and 1.0-6.0mm thickness detection range. This optical configuration guarantees consistent measurement regardless of part positioning on the glass plate.

Intelligent Sorting & Data Management

The 4-port discharge system (OK port, dimension NG port, surface NG port, uncertain port) enables precise classification based on inspection results. Integrated data management automatically logs all measurements and defect images, generating comprehensive quality reports for full production traceability.

Rapid Changeover & Model Generation

UIDG defect generation software dramatically reduces setup time when switching product batches by automatically generating defect samples for AI training. This eliminates the traditional bottleneck of collecting physical defect samples, enabling faster production line transitions and reduced downtime.

User-Friendly Operation Interface

The UZVISION platform features an intuitive interface that simplifies recipe creation and parameter adjustment. Operators can quickly configure inspection criteria without extensive programming knowledge, while the system's pattern recognition automatically adapts to part orientation variations.

Usage Scenarios

Automotive Rubber & Sealing Components

The UGO-EA-I excels at inspecting O-rings, flat gaskets, rectangular rings, bearing seals, and oil seals critical to automotive systems. Its 10-camera non-contact optical inspection system prevents deformation of soft rubber materials while accurately detecting burrs, raw edges, flow marks, cracks, pitting, mold dirty, material deficiencies, and surface impurities that could cause seal failure in engines, transmissions, braking systems, and hydraulic applications.

Electronics Micro-Precision Parts

The UGO-EA-I precisely inspects miniature rubber sealing rings, waterproof O-rings, and micro silicone gaskets for various devices. Its vibrating plate feeding system handles delicate components gently. The AI vision system detects microscopic defects, dimensional variations, and contamination that could affect waterproof and dust protection performance.

Electronics Plastic Parts

Small rubber-silicone composite sealing elements, button gaskets, and elastomeric protective components for consumer electronics undergo comprehensive dimensional and surface quality inspection, ensuring consistent sealing integrity and tactile performance in portable electronic devices.

Medical Injection Molded Consumables

The system rapidly measures rubber stoppers and O-rings for dimensional accuracy without physical contact, maintaining the hygiene and shape of sterile consumables.

Military Special Material Components

High-performance fluoroelastomer O-rings, extreme-temperature silicone seals, EPDM gaskets, and specialty rubber components designed for harsh military environments undergo comprehensive 10-camera inspection. The UGO-EA-I detects surface defects including cracks, fractures, pitting, impurities, material deficiencies, and dimensional deviations to ensure mission-critical sealing reliability for aerospace, naval, and ground defense applications.

Product Parameters

| Category | Item | UGO-E-I | UGO-F-I-I | UGO-F-I-III |

|---|---|---|---|---|

| Equipment Parameter | Model | UGO-E-I | UGO-F-I-I | UGO-F-I-III |

| Detection disc diameter | 600mm | 800mm | ||

| Equipment size | 1080*1080*2210 | 1100*1100*2110 | 1330*1330*2280 | |

| Equipment weight | 700KG | 720KG | 850KG | |

| Voltage | 220VAC (Standard) | 220VAC (Standard) | 220VAC (Standard) | |

| Frequency | 50HZ/60HZ | 50HZ/60HZ | 50HZ/60HZ | |

| Power | 3KW | 3KW | 3KW | |

| Air pressure | 0.5-0.8Mpa | 0.5-0.8Mpa | 0.5-0.8Mpa | |

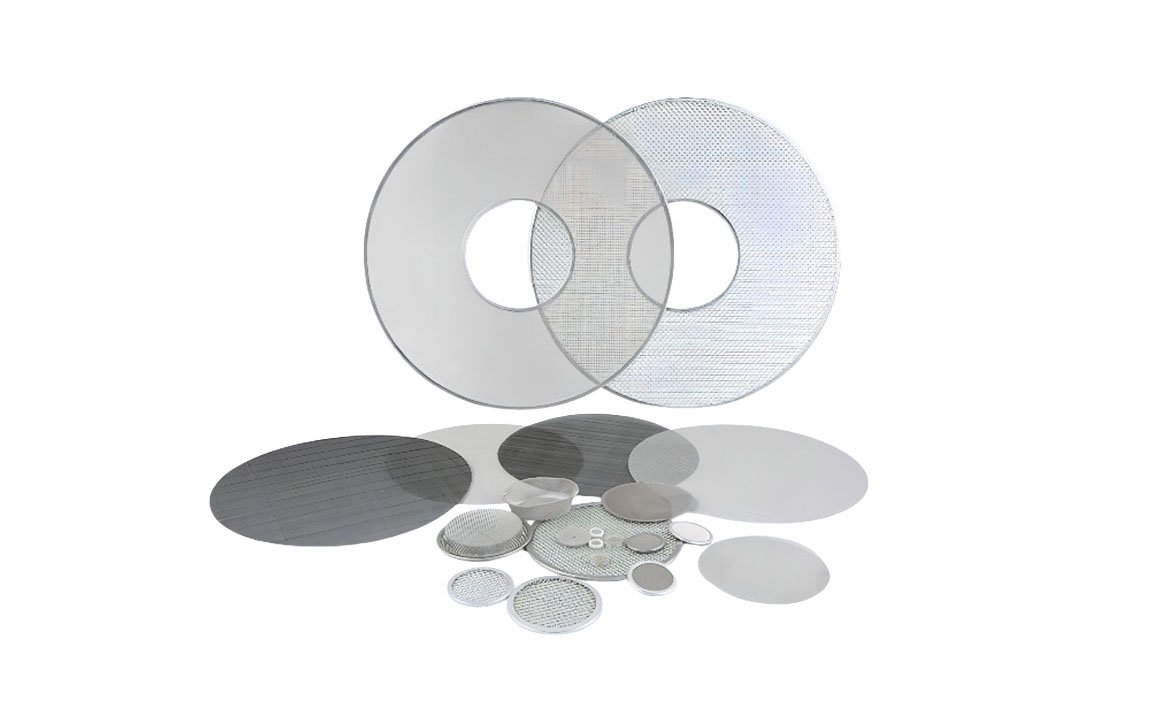

| Technical Characteristic | Applicable workpiece | O-rings, flat gaskets, rectangular rings, bearing seals, oil seals and other rubber products. | Same as left | Same as left |

| Detection appearance items | Burr, flash, flow mark, lack of material, stuck material, deformation, fracture, wear, dirty, impurities, etc. | Same as left | Same as left | |

| Detection size range | Outer diameter 5-65mm, thickness 1.0mm-6.0mm | Same as left | Same as left | |

| Feeding method | Vibrating plate feeding | Slope climbing machine feeding | Vibrating plate feeding | |

| Maximum number of cameras | 10 Pcs | 11 Pcs | 16 Pcs | |

| Speed | 120-1000pcs/min (Depending on product specifications or number of cameras) | Same as left | Same as left | |

| Accuracy | Repeatability ±0.01mm | Same as left | Same as left | |

| Discharge opening | 4 discharge ports (OK port, dimension NG port, plane NG port, uncertain port) | Same as left | Same as left | |

| Peripheral facilities | Vertical loading machine, packaging machine | Packaging machine | Vertical loading machine, packaging machine | |

| Computer | Standard industrial-grade computer (AI algorithm equipped with NVIDIA high-computing power graphics card) | Same as left | Same as left | |

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + Algorithm platform UIDI + AI detect generation software UDG. | Same as left | Same as left |

Matching Products

The UF-TZ-08 Passage Regulation Inspection Machine is designed for precise inspection of threaded holes and through holes. Utilizing a go/no-go gauge method, it efficiently determines whether the hole diameters meet standard specifications, distinguishing between acceptable and non-acceptable parts. This machine is crucial for maintaining quality control in industries where precise hole dimensions are critical.

✅ Automated Go/No-Go Gauging for Threads and Bores

✅ High-Sensitivity Torque Control to Prevent Part Damage

✅ Effective Detection of Internal Pitch, Depth, and Blockages

✅ Seamless Integration with Optical Sorting Lines

The UPD-H-2500 is a specialized belt-type optical sorting machine engineered for the rigorous inspection of elongated cylindrical parts, shafts, and rods. Unlike glass or index plate systems, the UPD-H-2500 utilizes a high-stability belt transmission system to support the full length of slender workpieces, effectively preventing rolling or misalignment during high-speed transport. Integrated with UNITECHO’s advanced vision system, it delivers continuous, uninterrupted detection of dimensional and surface defects, making it the ideal solution for automotive shafts, precision pins, and long fasteners.

✅ Specialized Belt Conveyor for Long Shaft & Rod Stability

✅ Continuous High-Speed Detection for Cylindrical Components

✅ AI-Powered UZVISION Platform with UIDG Defect Generation Software

✅ Non-Stop Flow Design for High-Volume Production Lines

The UTH-500 Steel Belt Type Optical Sorting Machine is a state-of-the-art solution designed for the precise inspection of spring components. With its high-resolution detection system, it efficiently identifies defects such as deformation, broken wires, and weld points, ensuring quality control for various spring types including compression and tension springs.

✅ High-Resolution Detection for Accurate Defect Identification

✅ Efficient Inspection of Compression and Tension Springs

✅ User-Friendly Interface for Easy Operation and Setup

✅ Nearly 360° Comprehensive Inspection

✅ High Precision and Efficiency in Detection

The UNITECHO UFP-D-IV is a top-tier inspection system for large, complex hanging parts with a 500mm detection disc and 4KW drive. It features up to 12 high-resolution cameras for comprehensive analysis, ensuring zero blind spots. This machine offers precise inspections at ±250 pcs/min with ±0.002mm accuracy, ideal for critical aerospace and automotive applications.

✅ Massive 500mm Index Plate for Large Component Capacity

✅ 12-Camera Support for Comprehensive 360° & Internal Inspection

✅ Heavy-Duty 4KW Power System for High-Torque Stable Rotation

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics

The UFP-B-IV Index Plate Optical Sorting Machine is designed for inspecting suspended components like screws and bolts. With a 4KW drive system, it ensures stable, continuous operation. Equipped with a 285mm detection disc and rail conveyor, it provides vibration-free 360° inspections at ±400 pcs/min with ±0.002mm accuracy. Utilizing UNITECHO’s AI ecosystem, it guarantees defect-free quality control for automotive, medical, and electronics.

✅ 285mm Index Plate with Rail Conveyors for Hanging Part Stability

✅ High-Performance 4KW Motor System for Heavy-Duty Operation

✅ 4-Camera Optical Array for Multi-Angle Dimension & Defect Analysis

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province