UFP-B-IV Index Plate Metal Parts Optical Sorting Machine

The UFP-B-IV Index Plate Optical Sorting Machine is designed for inspecting suspended components like screws and bolts. With a 4KW drive system, it ensures stable, continuous operation. Equipped with a 285mm detection disc and rail conveyor, it provides vibration-free 360° inspections at ±400 pcs/min with ±0.002mm accuracy. Utilizing UNITECHO’s AI ecosystem, it guarantees defect-free quality control for automotive, medical, and electronics.

✅ 285mm Index Plate with Rail Conveyors for Hanging Part Stability

✅ High-Performance 4KW Motor System for Heavy-Duty Operation

✅ 4-Camera Optical Array for Multi-Angle Dimension & Defect Analysis

✅ AI-Powered Deep Learning with NVIDIA High-Computing Graphics

Software Advantages

Optimized for Non-Standing Parts

The specialized rail conveyor securely hangs workpieces by their heads, eliminating the wobbling common with belt sorters. This ensures long screws and bolts remain perfectly vertical, guaranteeing precise geometric measurement during inspection.

Robust 4KW High-Torque Performance

Featuring an upgraded 4KW power system, the UFP-B-IV delivers superior drive capability for consistent rotation under heavy workloads. This high-torque performance ensures throughput stability and measurement repeatability even with large steel fasteners.

Industrial AI Ecosystem

Powered by NVIDIA graphics and deep learning, the system intelligently distinguishes functional defects from cosmetic variations. Proprietary UIDG software enables rapid defect sample generation, drastically minimizing training time for new product setups.

Precision Dimensional & Defect Screening

Achieving ≥ ±0.002mm accuracy, the system rigorously checks critical dimensions, OCR, and surface integrity. It excels at identifying internal "blocked holes" in hollow parts and detecting material cracks, pitting, and flow marks.

Seamless Smart Factory Integration

Designed for automation, the UFP-B-IV connects seamlessly with vertical feeders and packaging units via a flexible discharge system. This enables a fully unmanned quality control line, streamlining operations from initial feeding to final baling.

Usage Scenarios

Automotive Precision Machined Parts

For non-standing machined components like valve stems and transmission pins, the machine’s hanging stability ensures precise concentricity and runout measurements. The system detects minute dimensional deviations of ±0.002mm, ensuring these critical parts fit perfectly within engine and gearbox assemblies.

Automotive Fasteners

The 285mm Index Plate Optical Sorting Machine utilizes rails to securely hang and inspect automotive bolts, wheel studs, and flange screws. It provides 360-degree analysis of thread integrity and head dimensions at high speeds, preventing assembly line stoppages caused by damaged or out-of-spec fasteners.

3C Electronics Structural Components

Leveraging Instant One-Key Measuring technology, the system verifies complex geometric tolerances—including flatness, hole positions, and profile contours—on smartphone mid-frames and SIM trays for slim, high-density devices.

3C Electronics Micro-precision Parts

Handling micro-fasteners and precision connecting pins, the system utilizes high-magnification optics to verify dimensions down to the micron level. It ensures that miniature components used in wearable devices and precision instruments are free from deformation and manufacturing flaws.

Semiconductor Interconnects

The machine is highly effective for inspecting elongated connector pins, pogo pins, and terminal leads that require hanging stability. It accurately measures pin straightness and plating integrity to guarantee reliable electrical connectivity in high-density semiconductor packaging.

Medical Fasteners

Designed to handle delicate medical hardware, this system rigorously inspects surgical screws and dental implants for surface contamination and microscopic burrs. The high-resolution 4-camera setup ensures that every fastener meets strict hygiene and dimensional standards required for patient safety.

Military Precision Fasteners Optical Sorting Solution

For mission-critical aerospace and defense applications, the system inspects high-strength alloy fasteners for stress cracks, material voids, and precise geometry. It guarantees 100% compliance with rigorous military specifications, ensuring reliability in extreme operational environments.

Ammunition Components Optical Sorting Solution

The machine is optimized to inspect cartridge cases and projectile bodies, specifically utilizing its optical angles to check for "blocked holes" and casing deformations. The rail-fed design stabilizes these cylindrical parts to accurately detect internal flaws that could lead to dangerous firing malfunctions.

Product Parameters

| Model | UFC-C-IV | UFC-D-IV | UFP-B-IV | UFP-D-IV | |

|---|---|---|---|---|---|

| UFC-C-IV | UFC-D-IV | UFP-B-IV | UFP-D-IV | ||

| Equipment Parameter | Detection disc diameter | 300mm | 500mm | 285mm | 500mm |

| Equipment size | 8608601913 | 106010601913 | 106010601870 | 124412441870 | |

| Equipment weight | 700KG | 800KG | 750KG | 800KG | |

| Voltage | 220VAC (standard) | ||||

| Frequency | 50HZ/60HZ | ||||

| Power | 3KW | 4KW | |||

| Air pressure | 0.5-0.8Mpa | ||||

| Technical Characteristic | Applicable workpiece | Suitable for detecting workpieces that cannot stand, such as screws, bolts and other workpieces that can be hung. | |||

| Feeding method | Rail conveyors | ||||

| Feeding direction | clockwise/counterclockwise | ||||

| Inspectable items | Thickness, diameter, diagonal, blocked holes, cracks, characters, pits and other dimensional appearance defects | ||||

| Maximum number of cameras | 4 Pcs | 12 Pcs | 4 Pcs | 12 Pcs | |

| Speed | ±450Pcs/min | ±600Pcs/min | ±400Pcs/min | ±250Pcs/min | |

| Accuracy | ≥±0.002mm | ||||

| Accessories can be added | It can be equipped with vertical feeding machines, climbing machines, turnover systems, etc., and can be connected to packaging and baling machines. | ||||

| Computer | Standard I7 industrial-grade computer (AI algorithm equipped with NVIDIA high computing power graphics card) | ||||

| Software platform | All support UNITECHO's three self-developed software algorithm platforms: UZVISION vision platform + AI algorithm platform UIDI + AI defect generation software UIDG | ||||

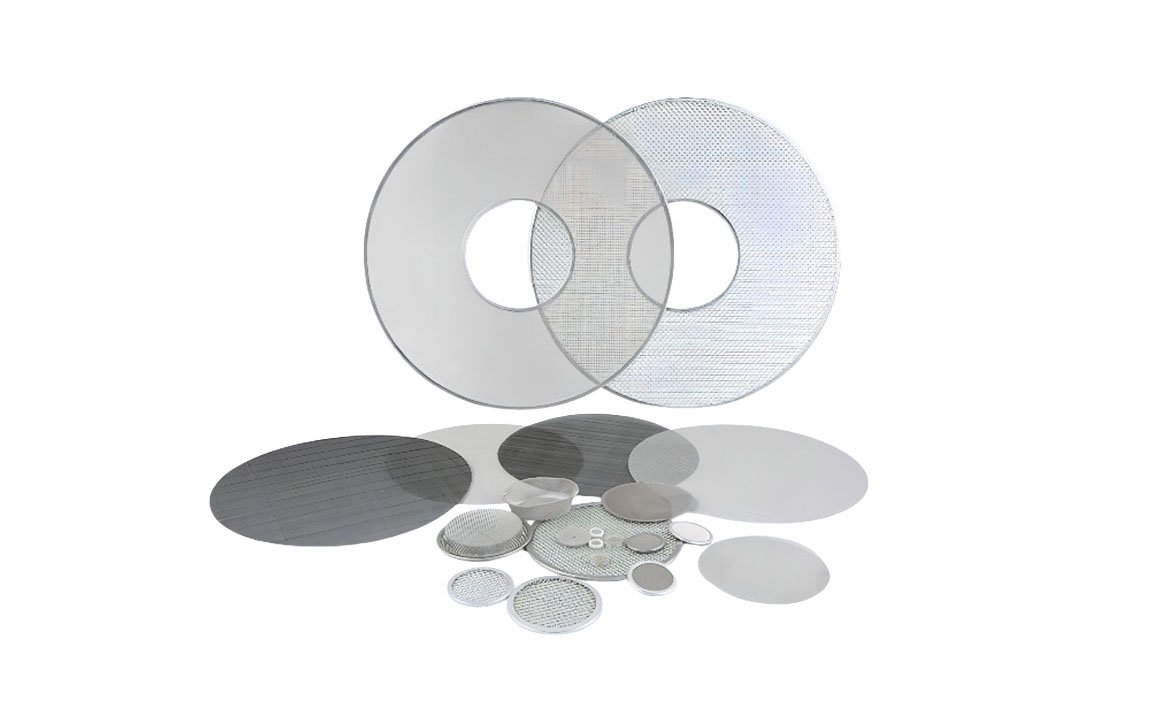

Matching Products

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province