Weighing and counting packaging machine

- Home /

- Packing Machine /

- Weighing and counting packaging machine

UNITECHO’s Weighing Counting Packaging Machines are engineered for the high-speed processing of bulk granular products where weight is the primary measure of quantity. These systems integrate high-sensitivity load cells with vertical packaging units to handle heavy loads (typically 1kg–3kg) efficiently.

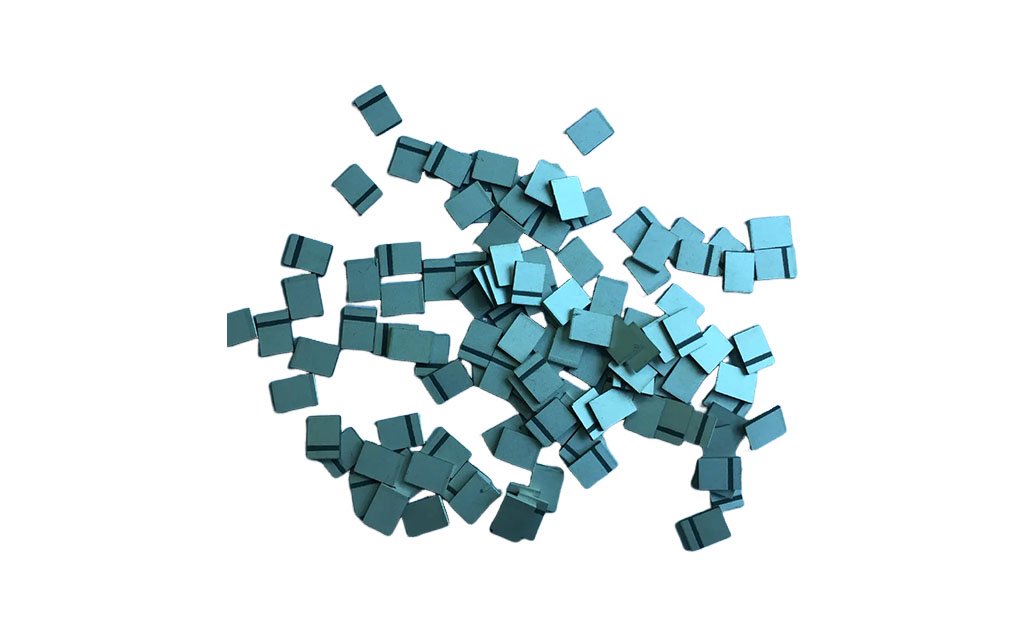

Unlike counting individual pieces, these machines focus on rapid “weight-based” filling, making them ideal for standard fasteners like screws and nuts where exact counts are less critical than total mass. With robust Z-type hoists for feeding and durable back-sealing technology, they ensure consistent, heavy-duty bagging for industrial supply chains.

Product Series

Redefining precision for hardware packaging

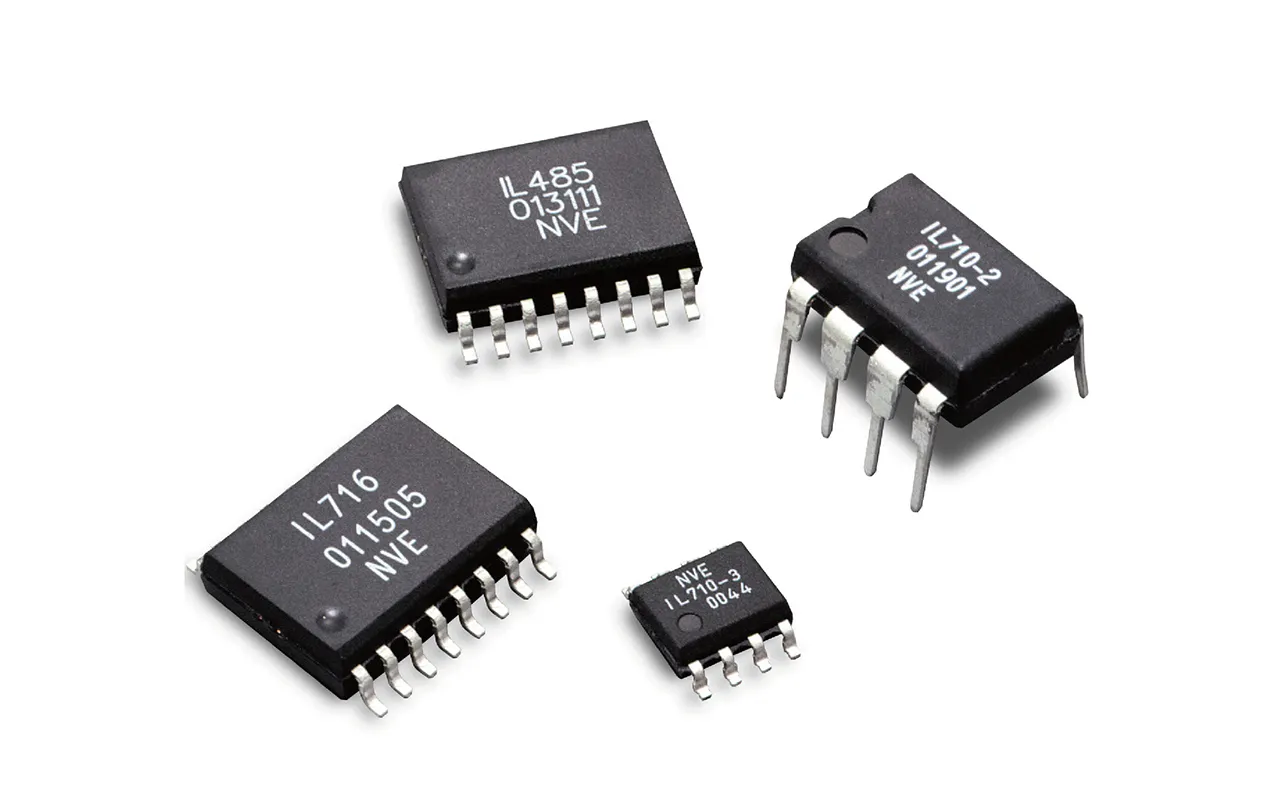

Smart control, modular design, and high-precision sensors for reliable quantitative packaging. Capable of fully automated feeding, weighing, and filling, this system is perfectly suited for screws, automotive fittings, and metal hardware. Experience the seamless integration of efficiency and traceability: Weighting and Counting Packing Machine.

✅ Flexible weighing range (50g–3000g) for diverse hardware

✅ Intelligent MCU control with 7-inch touch screen interface

✅ Fully automated operation at 5–20 bags/minute

Mastering versatility in Bag Type Weighing Packer

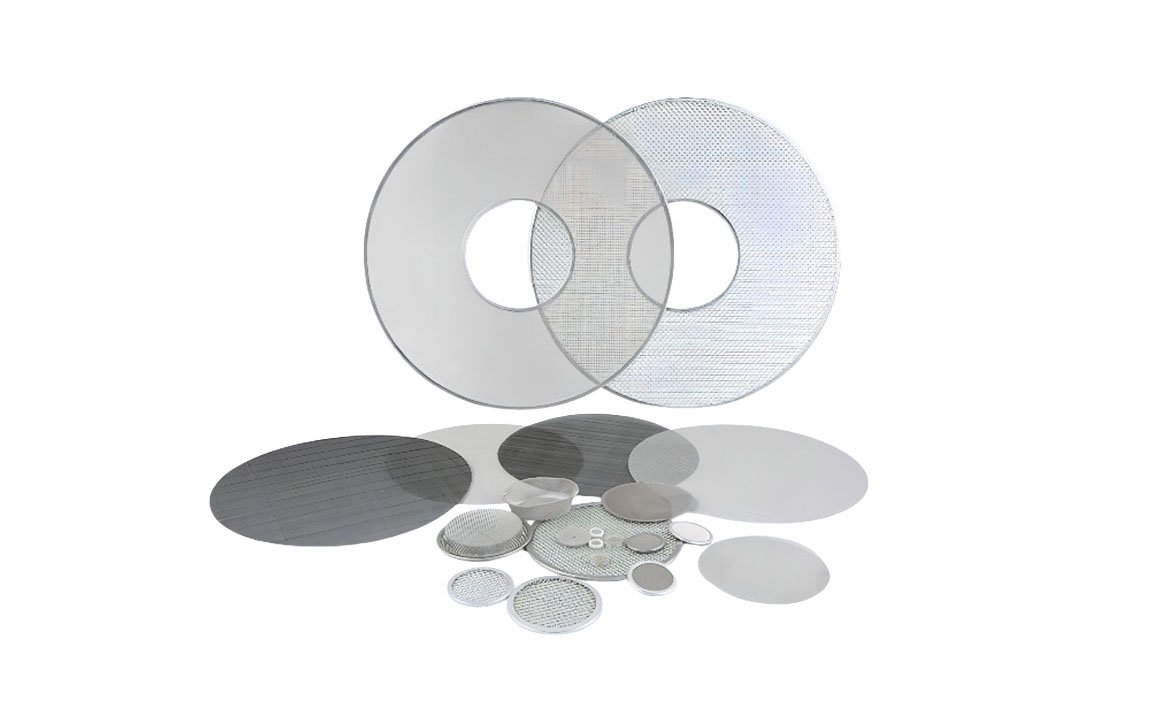

Features a fully integrated system with a Z-type conveyor and a high-precision computer combined scale for seamless operation. Suitable for a wide variety of small particle products, ranging from industrial hardware like screws and terminals to food items such as coffee, dumplings, and sugar.

✅ Flexible weighing range (50g–5000g) for various product sizes

✅ Steady production capacity of 10–20 bags/min

✅ Compatible with composite membrane, aluminum foil, and heat sealing films

UNITECHO’s Weighing And Packing Machines are engineered for the high-speed processing of bulk granular products where weight is the primary measure of quantity. These systems integrate high-sensitivity load cells with vertical packaging units to handle heavy loads (typically 1kg–3kg) efficiently.

Unlike counting individual pieces, these machines focus on rapid “weight-based” filling, making them ideal for standard fasteners like screws and nuts where exact counts are less critical than total mass. With robust Z-type hoists for feeding and durable back-sealing technology, they ensure consistent, heavy-duty bagging for industrial supply chains.

Product Comparison

Single-head trial weighing and packaging machine (GY-C01)

| The main technical parameters | |

|---|---|

| Production capacity | 200-300bag/h |

| Measuring range | 1KG-3KG |

| Bag making forms | Back seal |

| Total power | 2.4 KW |

| Net weight | 750 kg |

| Power supply voltage | 380V 50Hz 220V 50-60Hz |

| Bag size | length(L): 40-400mm; wide(W): 100-300mm |

| Packaging materials | Composite membrane materials, aluminum foil, heat sealing film |

| Dimensions | 1.1(L) × 3.0(W) × 1.6(H)m |

Single-head trial weighing and packaging machine (GY-C01)

| The main technical parameters | |

|---|---|

| Production capacity | 10-20 bag/min |

| Measuring range | 50g-5000g |

| Bag making forms | Back seal |

| Total power | 2.4 KW |

| Net weight | 500 kg |

| Power supply voltage | 380V 50Hz 220V 50-60Hz |

| Bag size | length(L): 40-400mm; wide(W): 100-300mm |

| Packaging materials | Composite membrane materials, aluminum foil, heat sealing film |

| Dimensions | 1.5(L) × 1.5(W) × 1.6(H)m |

Single-head trial weighing and packaging machine (GY-C01)

| The main technical parameters | |

|---|---|

| Model | MAX-WT35 |

| Range of single bag weight | 50-3000g |

| Weighing accuracy | 1-10g |

| Max weighing speed | 5-20 bags/min |

| Hopper capacity | 5L |

| Control system | MCU |

| Preset programs | 10 |

| Max Mix-products | 2 types |

| Operation panel | 7-Inch screen (optional 10-inch screen) |

| Power requirements | AC220V±10% 50HZ/60HZ |

Product Classification Advantages

High-Volume Throughput

Designed for bulk production, these systems utilize efficient vibratory feeders and bucket elevators to maintain a continuous flow, achieving speeds suitable for wholesale packaging.

Precision Weighing Modules

Equipped with advanced digital weighing sensors and "Self-determination" measuring ranges, the system minimizes giveaway and ensures every bag meets the target weight specifications.

Heavy-Duty Bagging

The vertical form-fill-seal mechanism is built to handle thick composite films, creating strong back-sealed bags that can support the weight of heavy hardware without bursting.

Automated Bulk Feeding

Integrated with Z-type bucket hoists, the system automates the lifting and feeding of materials from floor level, significantly reducing manual labor intensity.

Smart Flow Control

The system monitors material flow in real-time, automatically adjusting vibration amplitude to prevent overfilling and ensure consistent weight accuracy.

Versatile Material Handling

Capable of handling a wide variety of uniform granular products (screws, plastic pellets) as well as slightly irregular items, offering flexibility for different product lines.

Industry Applications

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province

Industry Insights & Resources