Visual Counting Packaging Machine

- Home /

- Packing Machine /

- Visual Counting Packaging Machine

This category represents UNITECHO’s flagship solution for zero-error kitting, combining precise Vibratory Bowl Counting with advanced verification systems. As highlighted by the GY-LS-01 and GY-LS-04 models, these machines are designed for the “Hybrid Packaging” of fasteners and irregular parts.

The GY-LS-01 (Single Disk) features a unique dual-check system: it counts products via the vibratory bowl and then verifies the final bag using an integrated Sorting Checkweigher, ensuring a “100% qualified rate” by automatically rejecting incorrect packs.

The GY-LS-04 (Multi-Disk) specializes in mixed kits, capable of feeding 1 to 12 different items (such as screws, anchors, and keys) into a single bag. This makes them the ultimate choice for complex hardware kits in the sanitary, lock, and furniture industries.

Product Series

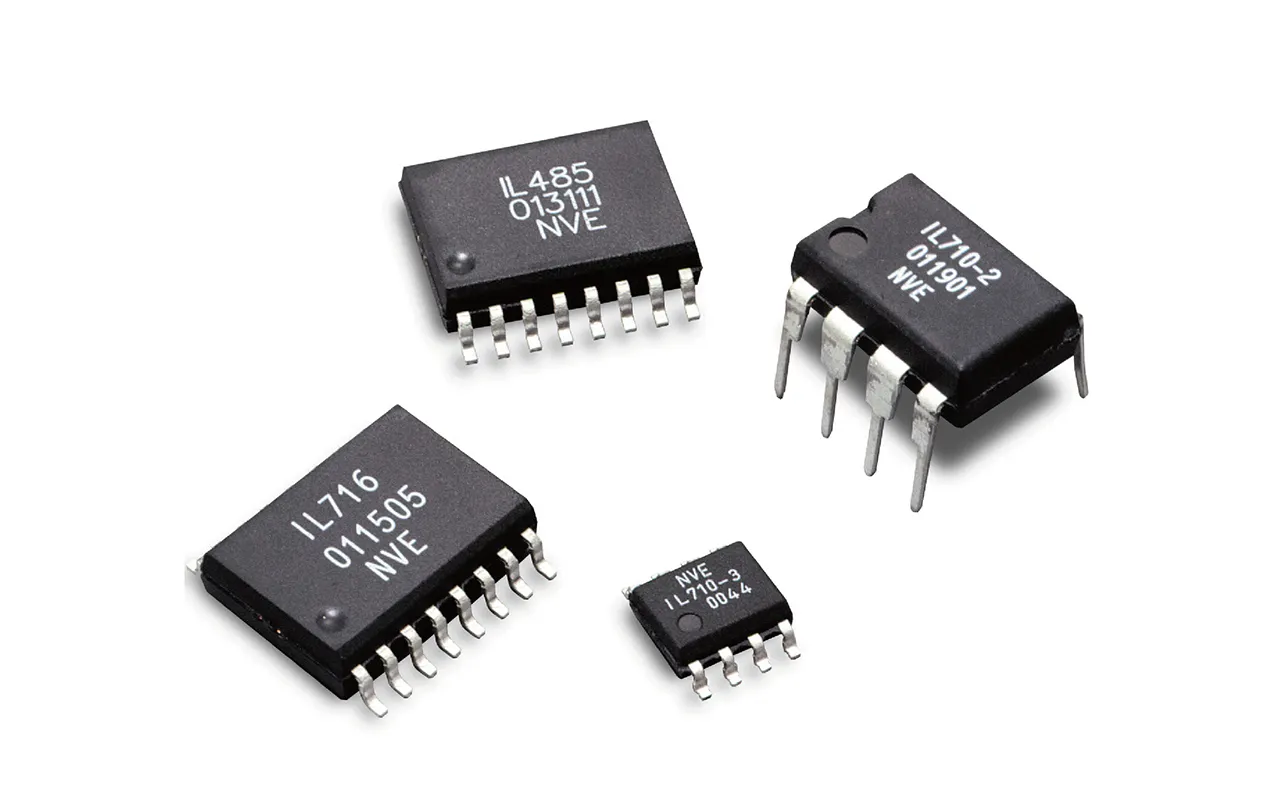

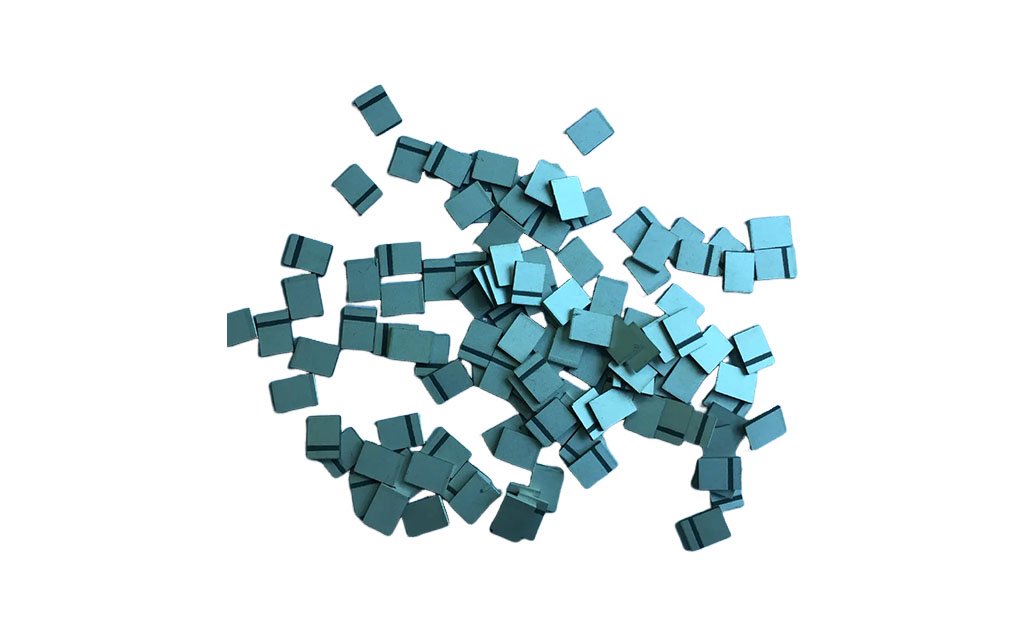

Powered by advanced High-Speed CCD Imaging technology, the PE Film Packing Machine eliminates the inaccuracies of traditional weighing methods. By calculating product area and volume in real-time, it achieves counting speeds of up to 10,000 pcs/min with Zero Negative Deviation. Ideal for high-value components such as electronic chips, precision injection molding, and medical hardware where exact quantity is non-negotiable.

- ✅ Ultra-High Efficiency: Counting speeds of 8,000–10,000 pcs/min

- ✅ Zero Negative Deviation: Guarantees no shortages (0–3‰ positive tolerance)

- ✅ Intelligent Traceability: Seamless ERP integration for data tracking

Sophisticated chain bucket conveying and multi-station vibratory feeding for precise mixed packaging in an instant. Suitable for a wide variety of components, including license plate screws, lighting fixtures, and electrical appliances. Discover the flexible solution for multi-item accessory kits: UNITECHO Chain Bucket Multi Vibration Packing Machine.

✅ High production capacity of 20–70 bags/min

✅ Capable of mixing 1–12 different component types in a single bag

✅ Versatile bag sizing (Length: 40–400mm) compatible with composite and foil films

Mastering the art of mixed hardware packaging

Universal vibratory feeding, customizable counting systems, and vertical bagging technology for complex hybrid packaging. Designed to handle 1 to 12 different types of components—from screws and plastic anchors to furniture fittings—in a single cycle, ensuring every kit is complete. Discover the ultimate solution for automated kit assembly: UNITECHO Multi Disk Vibration Plate Screw Packing Machine GY-LS-04.

✅ Efficient production capacity of 10–50 bags/min

✅ Capable of mixing 1–12 different component types in a single bag

✅ Versatile bag sizing (up to 400mm length) with composite film compatibility

Automating precision counting for granular packaging

Universal vibratory feeding, integrated vertical packaging, and final product sorting for guaranteed accuracy in every bag. Designed for granular hardware like screws and nuts, this system includes a post-pack checkweigher to ensure 100% quality compliance by automatically rejecting incorrect weights. Discover the reliable solution for counting and bagging: Single Disk Number Packing Machine.

✅ Efficient production capacity of 20–50 bags/min

✅ Integrated checkweigher ensures 100% qualified product yield

✅ Flexible bag sizing (Length: 40–900mm) for versatile applications

Product Comparison

Single-tray counting and packaging machine (GY-LS-01)

| The main technical parameters | |

|---|---|

| Model | MAX-VY25 |

| Efficiency | 8000-10000pcs/min |

| Detectable size | 2mm-50mm |

| Technical precision | 0-3% (No negative deviation) |

| Power requirements | AC220V±10% 50HZ/60HZ |

| Overall weight | 300kg |

Multi-vibrating disc counting and packaging machine (GY-LS-04)

| The main technical parameters | |

|---|---|

| Production capacity | 20-70 bag/min |

| Measuring range | 1-12 pieces (unlimited number of grains) |

| Bag making forms | Back seal |

| Total power | 2.4 KW |

| Net weight | 500 kg |

| Power supply voltage | 380V 50Hz; 220V 50-60Hz |

| Bag size | length(L): 40-400mm; wide(W): 100-300mm |

| Packaging materials | Composite membrane materials, aluminum foil, heat sealing film |

| Dimensions | 1.1(L) × 1.5(W) × 1.6(H)m |

Chain bucket multi-vibrating packaging machine (GY-TD-10)

| The main technical parameters | |

|---|---|

| Production capacity | 10-50 bag/min |

| Measuring range | 1-12 pieces (unlimited number of grains) |

| Bag making forms | Back seal |

| Total power | 2.4 KW |

| Net weight | 500 kg |

| Power supply voltage | 380V 50Hz; 220V 50-60Hz |

| Bag size | length(L): 40-400mm; wide(W): 100-300mm |

| Packaging materials | Composite membrane materials, aluminum foil, heat sealing film |

| Dimensions | 1.1(L) × 1.5(W) × 1.6(H)m |

Visual counting packaging machine (MAX-VY25)

| The main technical parameters | |

|---|---|

| Production capacity | 20-50 bag/min |

| Measuring range | Self determination |

| Bag making forms | Back seal |

| Total power | 1.2 KW |

| Net weight | 270 kg |

| Power supply voltage | 220V 50-60Hz |

| Bag size | length(L): 40-900mm; wide(W): 100-300mm |

| Packaging materials | Composite membrane materials, aluminum foil, heat sealing film |

| Dimensions | 2.0(L) × 1.0(W) × 1.5(H)m |

Product Classification Advantages

Double Quality Assurance (Count + Weigh):

As seen in the GY-LS-01, the system integrates a "Sorting Checkweigher" at the conveyor output. This provides a secondary verification ("Once again, all kinds of packaged products are confirmed"), ensuring that any bag with a missing screw is automatically rejected.

Complex Hybrid Kitting

The GY-LS-04 Multi-Vibration Plate system can simultaneously handle up to 12 different varieties of components. It enables the creation of "Hardware Hybrid Packages" (e.g., a lock kit containing keys, screws, and panels) in a single automated process.

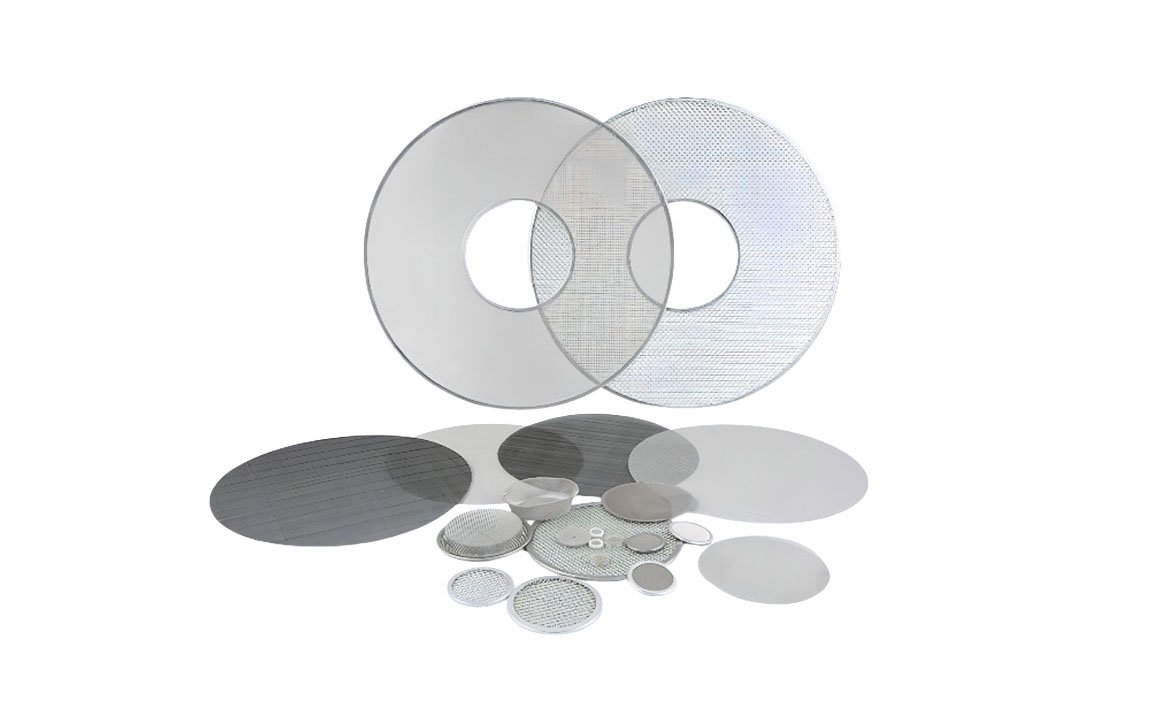

Universal Vibratory Disks

Our "Universal" bowls are engineered to handle a vast range of geometries. From standard screws/nuts to "special-shaped" items like door closer arms or sanitary fittings, the feeders can be customized to orient and count difficult parts effectively.

Flexible Production Speed

Supporting speeds of 20–50 bags/min (depending on complexity), the system balances high throughput with the precision required for mixed kits, significantly outperforming manual kitting.

Customizable for "Special Shapes"

We offer tailored engineering for non-standard items ("Special shapes can be arranged"). Whether it’s long bolts or odd-shaped decoration products, the vibration plates are custom-tooled to prevent jams.

Wide Packaging Scope

The vertical packing unit supports bag sizes from 40-900mm (L) and 100-300mm (W), making it versatile enough to package everything from tiny screw packets to large door lock installation kits.

Industry Applications

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province

Industry Insights & Resources