Combined packaging machine

- Home /

- Packing Machine /

- Combined packaging machine

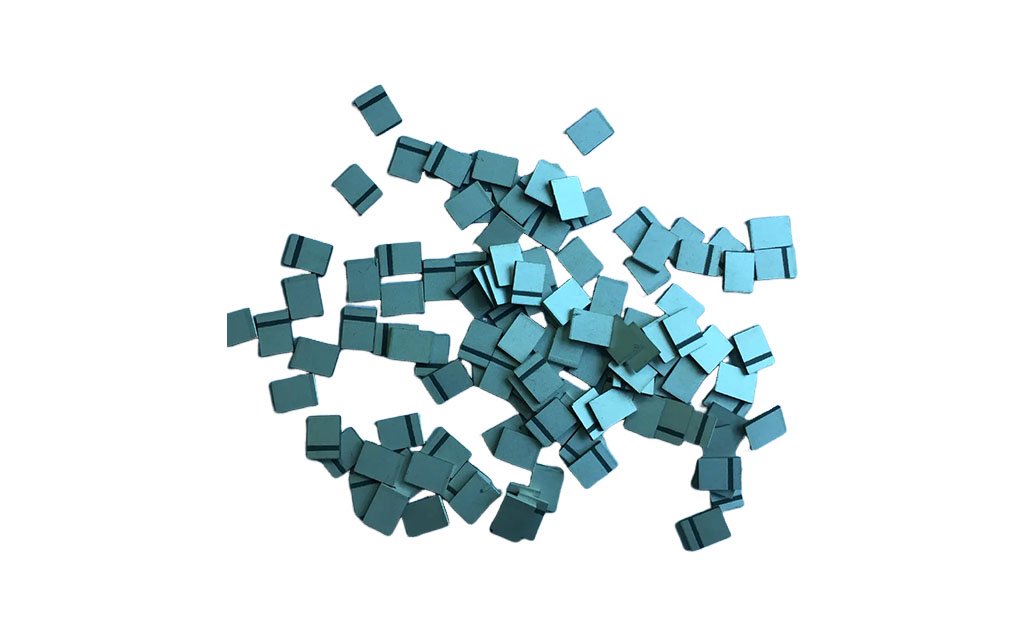

UNITECHO’s Combination and Semi-Automatic Packaging Machines offer the ultimate flexibility for “High-Mix, Low-Volume” production and difficult-to-handle products. Bridging the gap between manual labor and full automation, models like the GY-TX (Manual Selection) and GY-TD (Bucket Conveyor) allow operators to manually feed irregular items—such as long springs, soft rubber gaskets, or entangled parts—into an automated bagging system. These solutions are perfect for manufacturers who need professional packaging quality (Back Seal) but require the adaptability of human sorting for complex or fragile items that cannot be processed by vibratory bowls.

Product Series

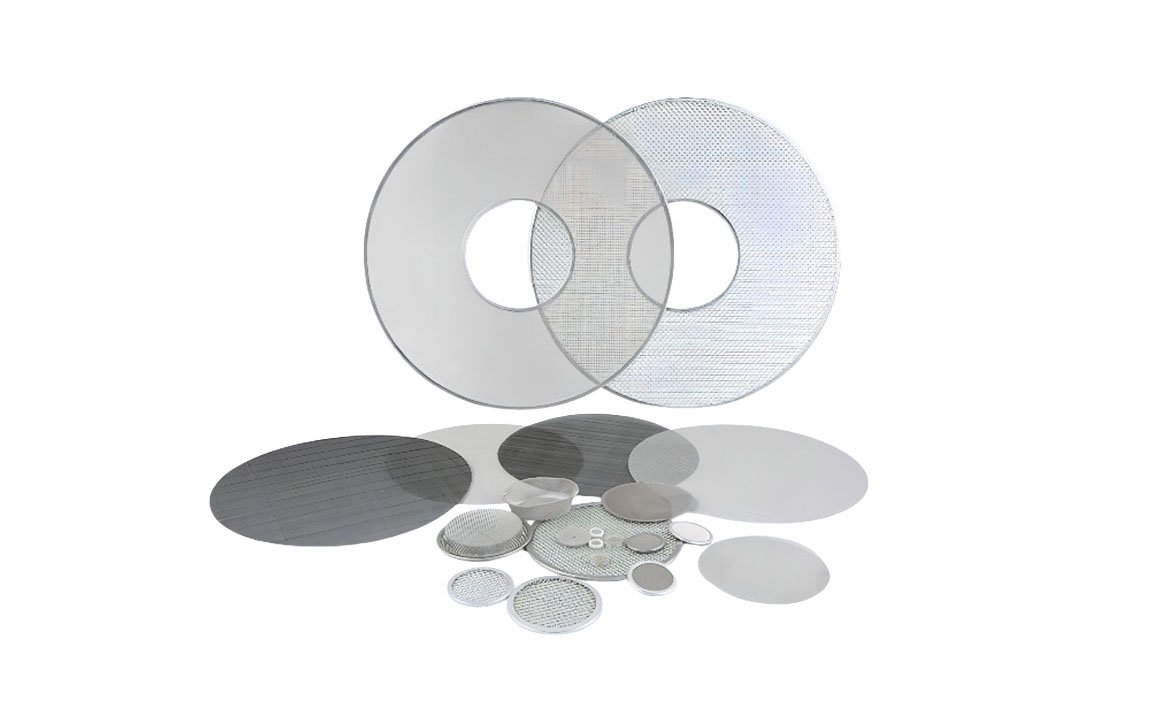

An intuitive PLC control system, high-quality vacuum pump, and flexible workstation design deliver a precise and efficient packaging experience. Designed specifically for materials such as agricultural seeds, small hardware, and electronic components, it is suitable for various bag types including three-side seal and stand-up pouches. The PG series (PG200-PG600) covers a wide bag width range from 70mm to 500mm, and its intelligent detection function ensures that bags are not filled if they are not opened, effectively preventing packaging material waste.

- Wide size adaptability (70-500mm), flexibly compatible with various bag types

- Intelligent anomaly diagnosis function: no filling if the bag is not opened, allowing for bag reuse

- Compact structure, small footprint, simple maintenance, and high return on investment

Entering the era of efficient automated packaging

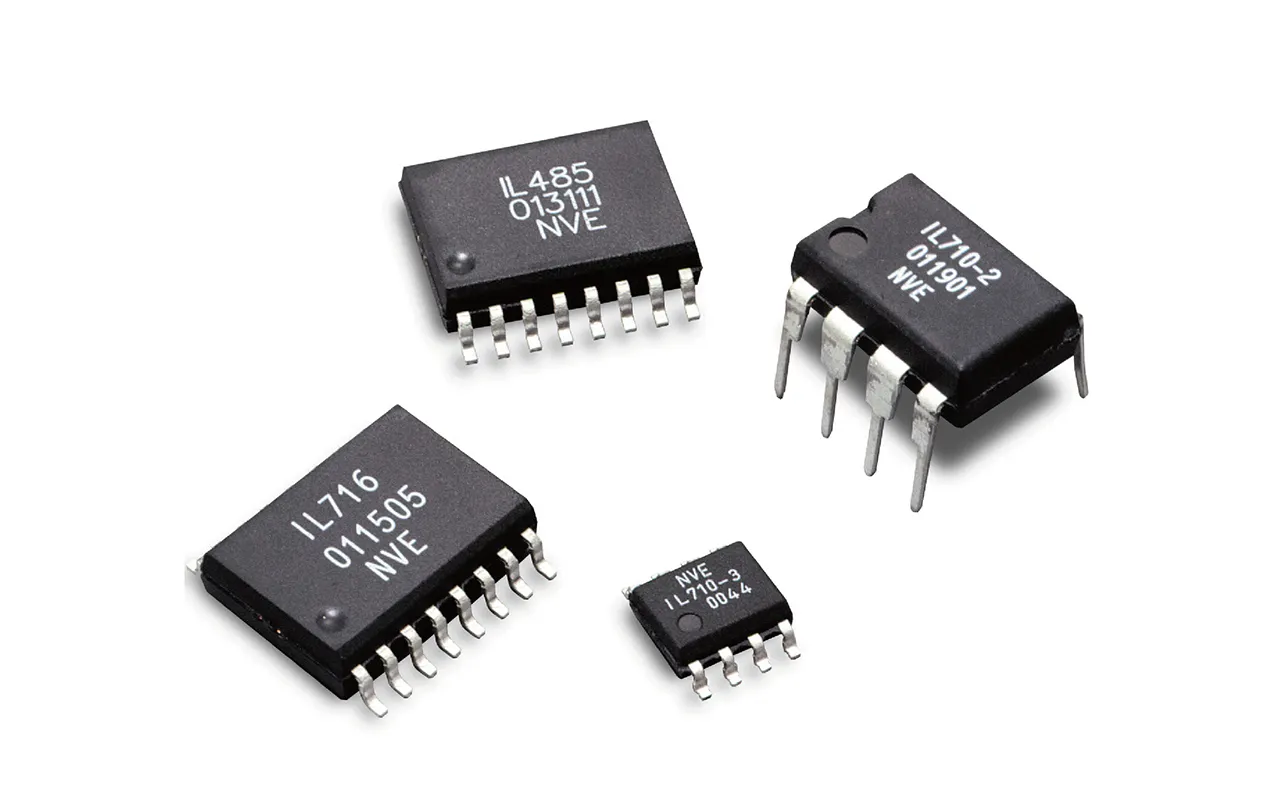

Advanced touch screen control, optimized structural design, and easy maintenance for precise packaging in an instant. Suitable for a wide variety of industrial components such as screws, terminals, and plastic parts. The PL series (PL320-PL620) accommodates bag widths from 50mm to 300mm and integrates bag making, sealing, and printing to save time and costs. Discover the new standard in industrial packaging: The PL Series Vertical Packaging Machine.

- Wide adaptability for bag sizes ranging from 50mm to 300mm

- Smart touch control and independent temperature regulation for flexibility

- All-in-one bag making, sealing, and cutting for maximum cost-efficiency

Compact efficiency for 5-8 bag/min PE Film Packing Machine

Intelligent operation, compact footprint, and significant material cost savings through the use of PE tubular film. The 5-8 bag/min PE Film Packing Machine is designed to handle varied bag sizes while occupying less than 1.2 square meters of floor space. Ideal for packaging hardware, plastic components, and medical parts, it supports both manual and automated feeding with seamless ERP integration.

✅ Flexible bag widths (150–250mm) with adjustable lengths

✅ High-capacity filling range from 10g to 10kg

✅ Intuitive 10.4-inch color touch screen interface

Streamlining manual packaging with integrated lifting

Combines the flexibility of manual feeding with an automated hoist system to reduce labor intensity and improve workflow. Designed for screws, nuts, and granular hardware of unlimited shapes, this system ensures smooth conveyance and versatile bagging without the physical strain of manual loading.

✅ Integrated hoist system reduces manual labor intensity

✅ Unlimited product shape compatibility via manual feeding

✅ Extensive bag length range (40–900mm) for versatile applications

Combining manual precision with automated packaging efficiency

Integrated manual selection platform and vertical bagging system for flexible packaging in an instant. Designed for non-standard hardware like springs and buckles that require human inspection or manual feeding, offering unlimited product shape compatibility.

✅ Unlimited product shape compatibility via manual sorting platform

✅ Extensive bag length range (40–900mm) for versatile applications

✅ Compatible with composite, aluminum foil, and heat sealing films

Efficient bulk packaging for large-format granular products

Robust bucket conveying and reliable sealing technology for heavy-duty bulk packaging in an instant. Designed specifically for granular bulk materials such as pneumatic connectors, water pipe fittings, and anti-theft buckles, ensuring secure containment in large-format bags.

✅ Optimized for large bag sizes (Length: 500mm, Width: 350mm)

✅ Utilizes cost-effective, eco-friendly PE film

✅ Ideal for bulk granular items like water pipe and pneumatic connectors

Maximizing flexibility for non-standard hardware packaging

Features an ergonomic electric lifting platform and manual feeding system designed for irregular or complex shapes. Perfect for items like springs, buckles, and non-standard hardware that cannot be automatically fed, offering unlimited versatility and rapid changeovers.

✅ Unlimited product shape compatibility via manual feeding

✅ Extensive bag length range (40–900mm) for versatile packaging

✅ Compatible with composite, aluminum foil, and heat sealing films

Maximizing flexibility for non-standard hardware packaging

Features an ergonomic electric lifting platform and manual feeding system designed for irregular or complex shapes. Perfect for items like springs, buckles, and non-standard hardware that cannot be automatically fed, offering unlimited versatility and rapid changeovers.

✅ Unlimited product shape compatibility via manual feeding

✅ Extensive bag length range (40–900mm) for versatile packaging

✅ Compatible with composite, aluminum foil, and heat sealing films

Product Comparison

| The main technical parameters | Semi-automatic packaging machine (GY-ZY-0) 1 | Semi-automatic packaging machine (GY-ZY-0.1) |

|---|---|---|

| Production capacity | 1-12bag/min | 5-12bag/min |

| Measuring range | Self determination | Self determination |

| Bag making forms | Back seal | Back seal |

| Total power | 1.5 KW | 1.2 KW |

| Net weight | 150 kg | 270 kg |

| Power supply voltage | 220V 50-60Hz | 220V 50-60Hz |

| Bag size | length(L): 500mm; wide(W): 350mm | length(L): 40-900mm; wide(W): 100-300mm |

| Packaging materials | PE film (environmental protection, low cost) | Composite membrane materials, aluminum foil, heat sealing film |

| Dimensions | 80(L) × 90(W) × 110(H)m | 2.0(L) × 1.0(W) × 1.5(H)m |

Product Classification Advantages

Handling Irregular & Tangled Parts

Ideal for items that cannot be automatically fed (e.g., long wires, sticky rubber parts, or large fittings). Operators manually place items, ensuring no jams or damage.

Hybrid Efficiency

Combines the decision-making capability of human operators with the speed and sealing quality of an automated vertical packer. This significantly increases output compared to fully manual bagging.

Large Bag & Bucket Capacity

Models like the GY-TD are equipped with wide conveyor buckets, designed to accommodate large items like water pipe connectors, anti-theft buckles, and bulky plumbing fittings (up to 400mm width bags).

Low Cost & Easy Deployment

These semi-auto systems are a cost-effective entry point into automation. They require minimal setup time and are easy for operators to learn and use immediately.

Scalable Modular Design:

The systems are designed to grow with your business. You can start with a semi-auto hand-feed station (GY-ZY-0) and later integrate automatic hoists (GY-ZY-0T) or feeders as production demands increase.

Professional Sealing Quality

Even with manual feeding, the machine utilizes precision temperature control and back-sealing technology to produce consistent, professional-grade packages that enhance brand value.

Industry Applications

Contact Experts For More Details

Get Inquiry

Unitecho Technology

UNITECHO Co., Ltd. was founded in 2013 and is headquartered in Suzhou, China. With machine vision Al technology as its core, it is committed to deeply integrating machine vision, automation, artificial intelligence and other technologies with industry applications. It is a new high-tech enterprise focusing on R&D, production, sales and service.

Phone

+86-159-0216-9777

Address

No.5 Linghou Road. Fenhu High-tech Zone. Wujiang District. Suzhou City. Jiangsu Province

Industry Insights & Resources

.png)